Investigation of The Performance of Journal Bearing Using Theoretical and Numerical Method

ABSTRACT

Hydrodynamic journal bearings have been widely used to support high-speed rotating machinery such as turbines and compressors because of their superior durability and load-carrying capacity.

Therefore, the bearings are essential to machine elements for enhancing the quality of the rotating machinery.

In this Summarey, I declare the importance and advantages of journal bearing and overview Reynold hydrostatic equation and apply Boundary Value finite-difference Solution to solve the second-order nonlinear differential equation using numerical iterations approach with MATLAB software.

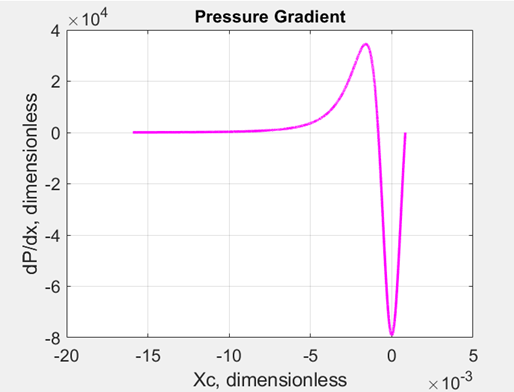

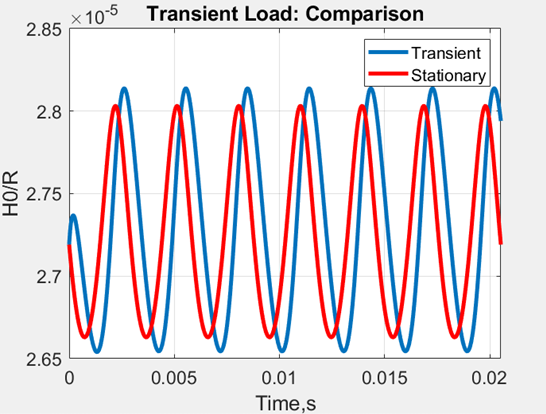

Analytical Solution and Semi-Analytical Solution of 1D transient Reynolds Equation have been mentioned to investigate the Pressure distribution, pressure gradient and the comparison between transient and steady loads on journal bearings.

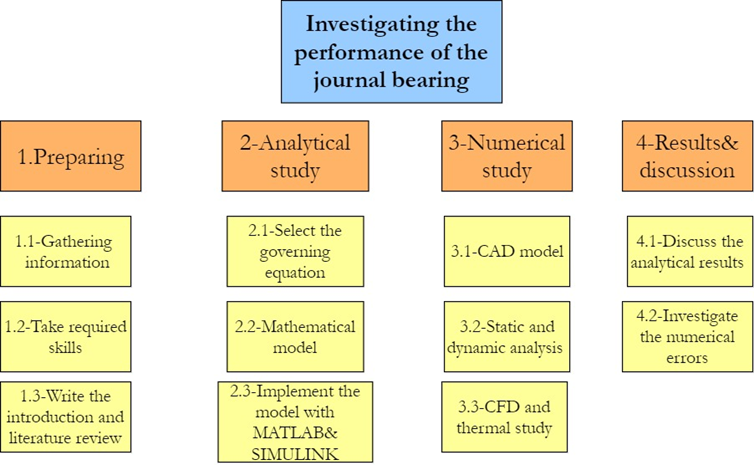

Methodology

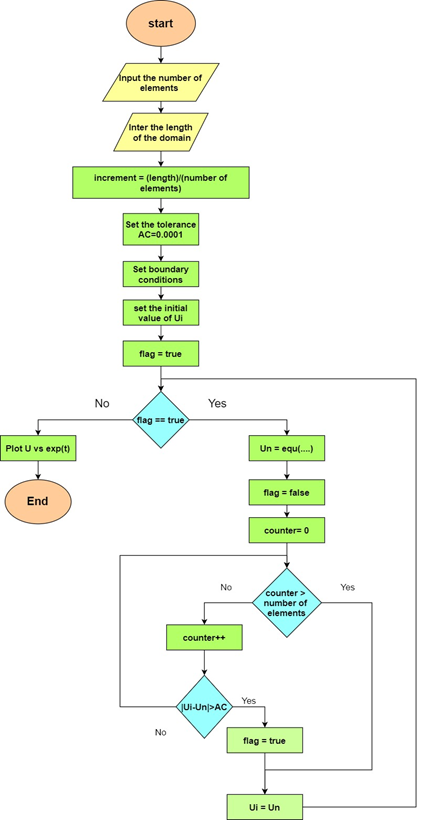

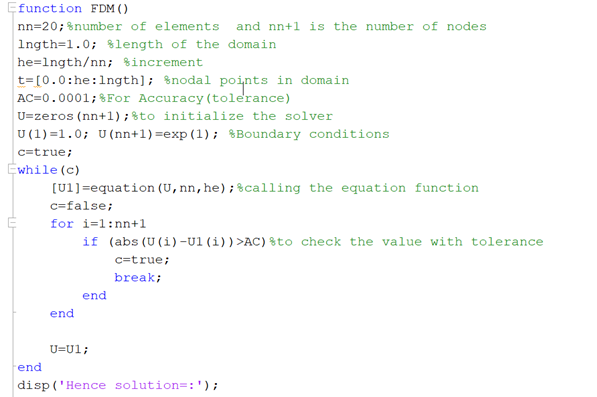

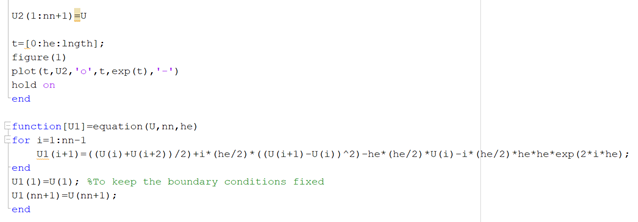

Boundary Value Solution Explicit Finite Difference Method

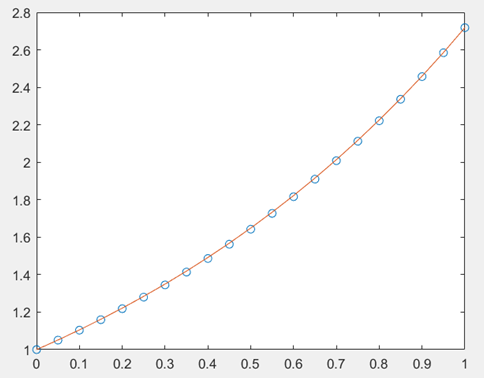

The result of plotting the final value for each point after several iterations is shown in the figure for 20 and 30 elements, respectively. The circles are the results values and the solid line is the real values.

Finite difference results in 20 elements

Finite difference results with 30 elements

Finite difference results with 30 elements

Analytical Solution of 1D Reynolds Equation

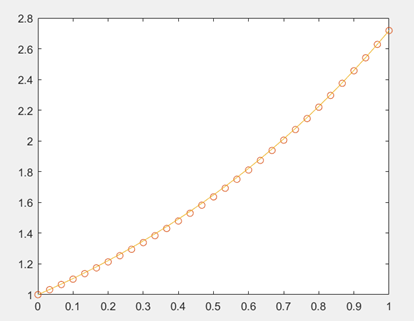

Semi-Analytical Solution of 1D Transient Reynolds Equation (Grubin's Approximation)

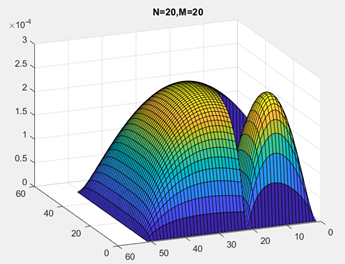

Pressure distribution with 20*20nodes

Pressure distribution with 20*20nodes

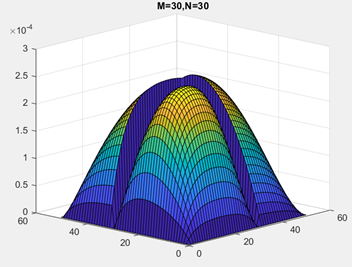

Pressure distribution with 30*30 nodes

Pressure distribution with 30*30 nodes

As shown in figures there are issues with the pressure distribution with 20*20 and30*30 number of nodes so by increasing the number of nodes to 50*50 the results will be as shown in figure15 and16 for a tolerance of 1% and0.1%.

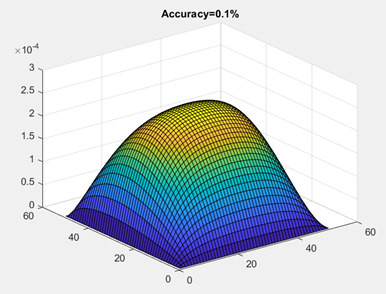

Pressure distribution with tolerance of 0.1%

Pressure distribution with tolerance of 0.1%

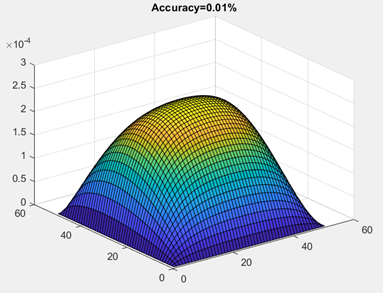

Pressure distribution with tolerance of 0.01%

Pressure distribution with tolerance of 0.01%

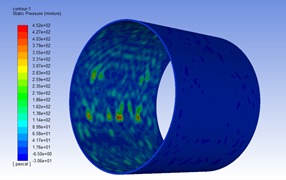

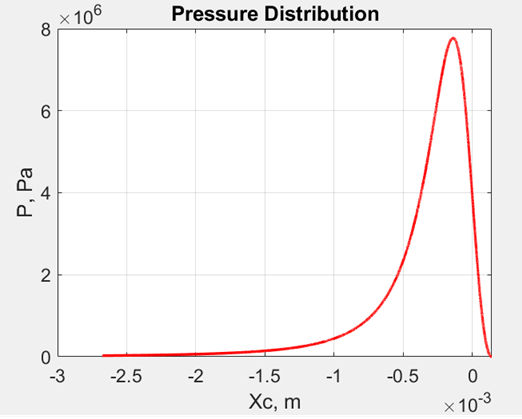

Numerical CFD analysis

Geometry preparation

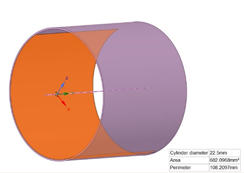

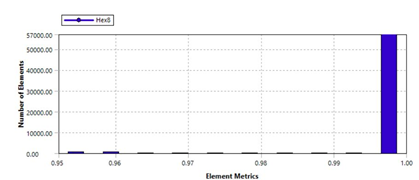

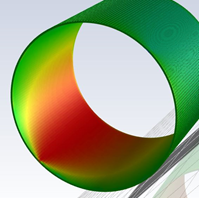

The journal bearing has been designed using SpaceClaim CAD workflow. Simple concentric cylinder with outer diameter of 23mm and inner diameter 22.5mm with a surface area of 750mm2.

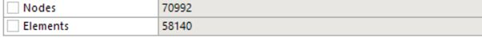

A structured mesh has been added to the geometry with a quadratic element. A mesh with 70992 nodes and 58140 elements has been used as shown in figure42, 43.

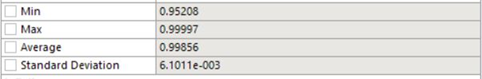

The mesh has excellent quality with minimum orthogonality of 0.95208 and maximum of 0.9997, and an average value of 0.99856, as shown in figure.

Boundary conditions

Boundary conditions

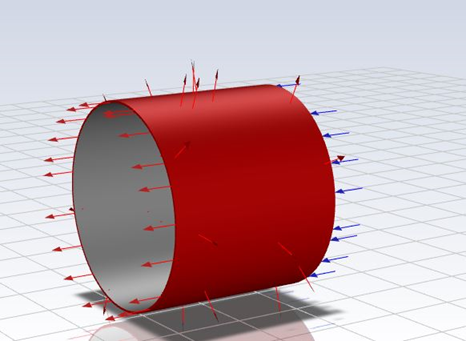

Residuals and convergence

Residuals and convergence

Numerical coupled solver has been used with first-order momentum and turbulent energy conservation equations.

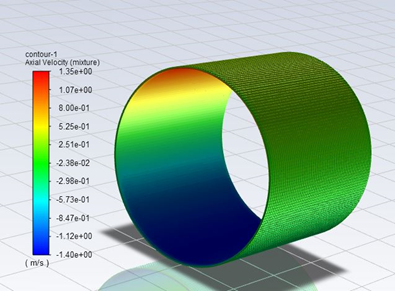

By assuming a rotation of 1500rpm with oil lubricant, the following parameters investigated.

Static pressure

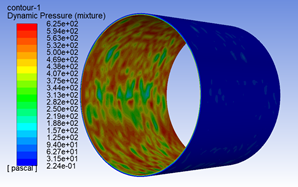

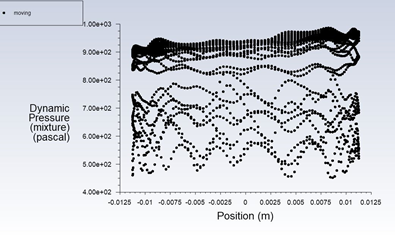

Dynamic pressure

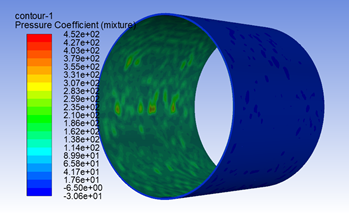

Pressure coefficient

Velocity and Reynold's

CONCLUSION

The journal bearing is one of the most critical applications of hydrodynamic lubricant devices. Reynold equation has the primary role in investigating the pressure gradient and pressure distribution in the journal bearing.

A simple boundary condition solution has been motioned firstly, but it has a limit to 30 elements.

The 1D analytical solution has also been declared, and the pressure distribution and gradient plotted and investigated.

Also, the comparison between the transient and steady-state has been motioned. After that general finite-difference solution has been applied, and the pressure gradient profile plotted and has the most appropriate shape with 50*50 element mesh and 0.001%tolerance.

Ansys fluent has been used to apply numerical analysis to the journal bearing, static pressure, dynamic pressure, velocity, turbulence effect, and acoustics power have been taken in consideration and declared at the final section of the Summary.