Solidworks Projects

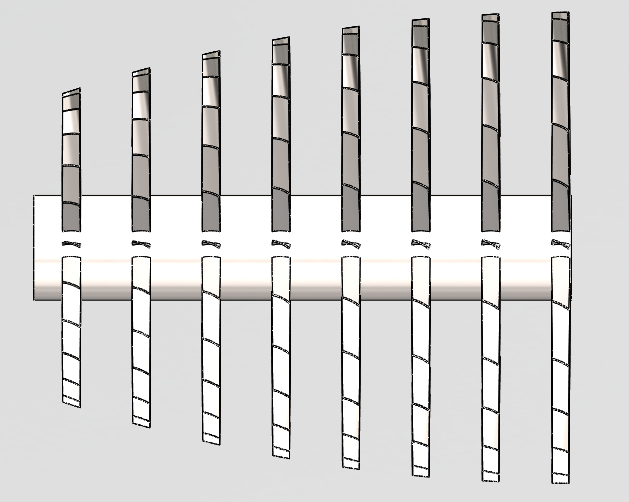

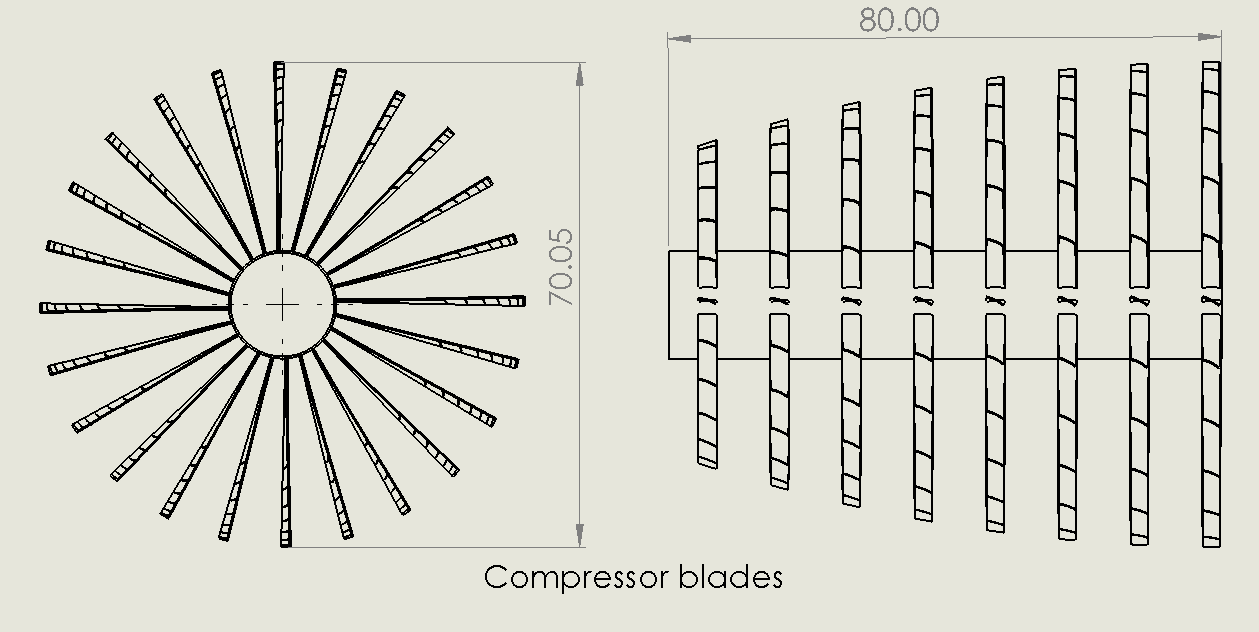

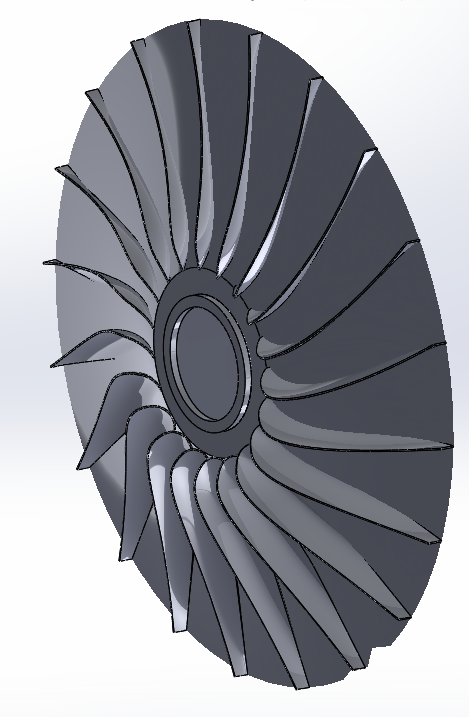

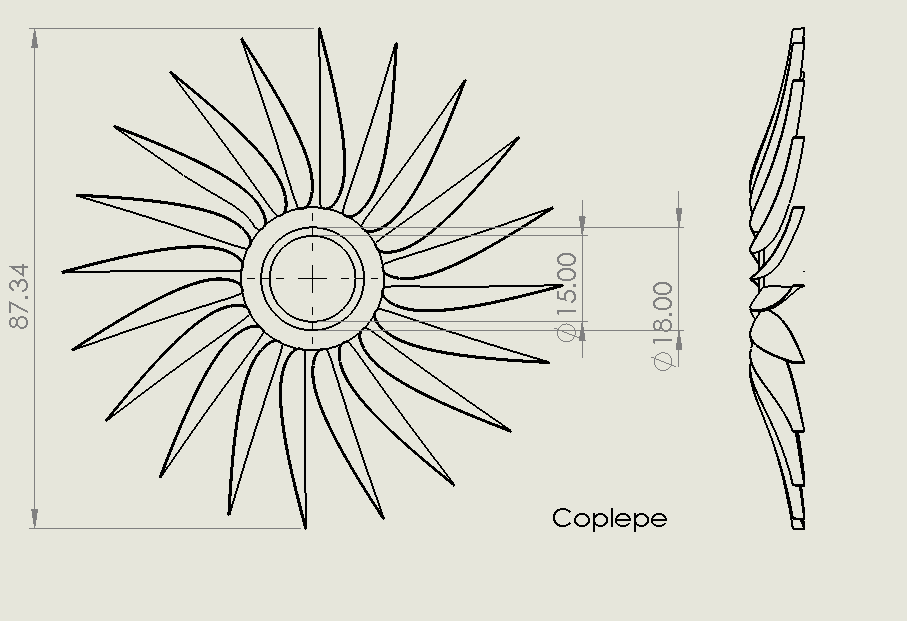

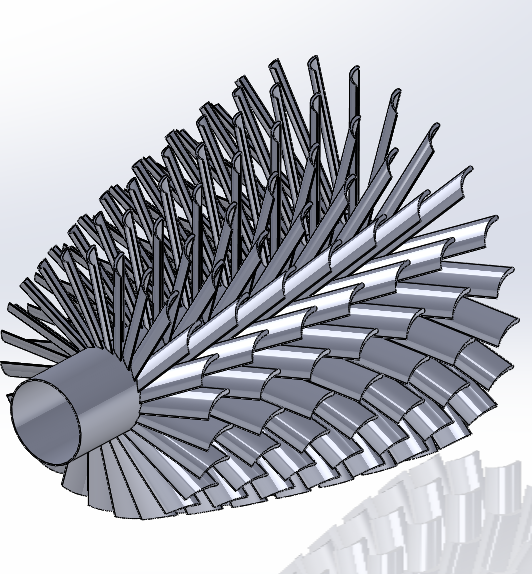

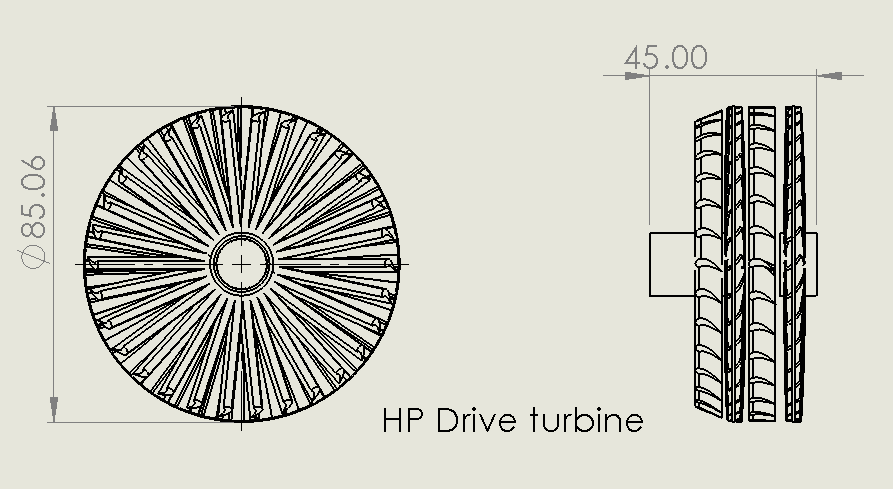

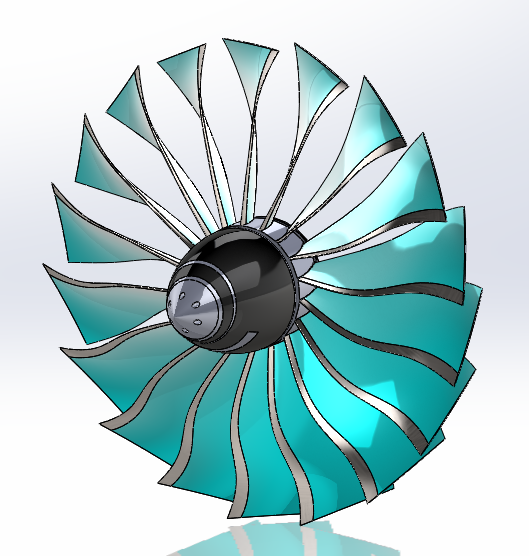

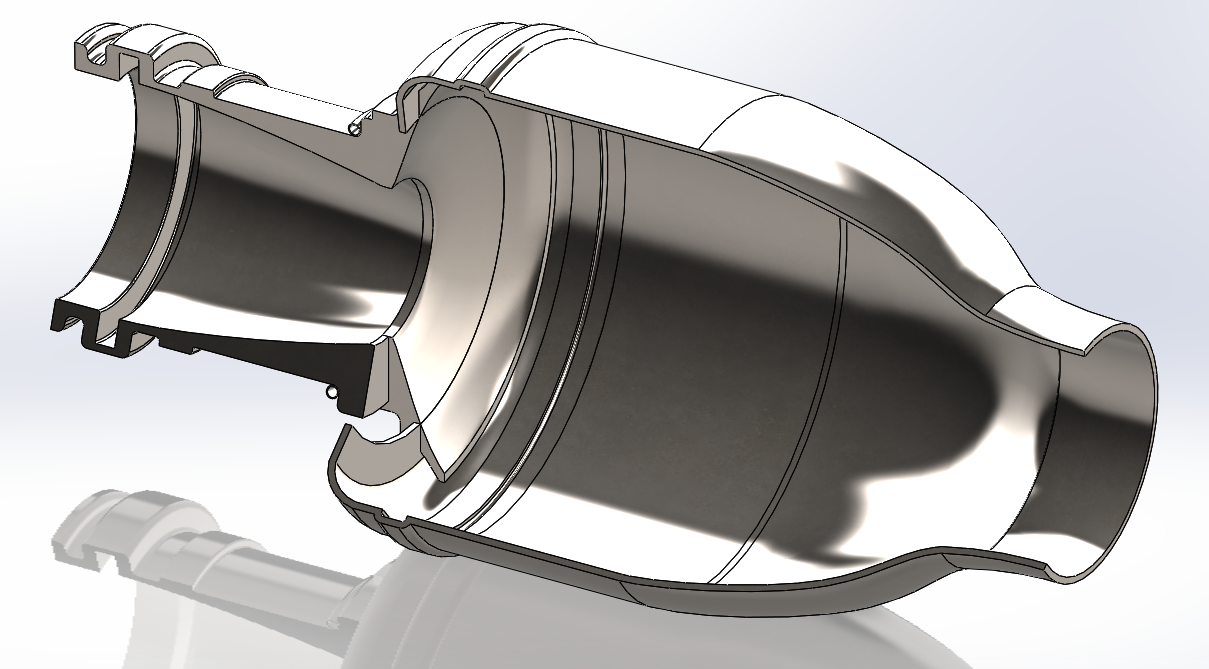

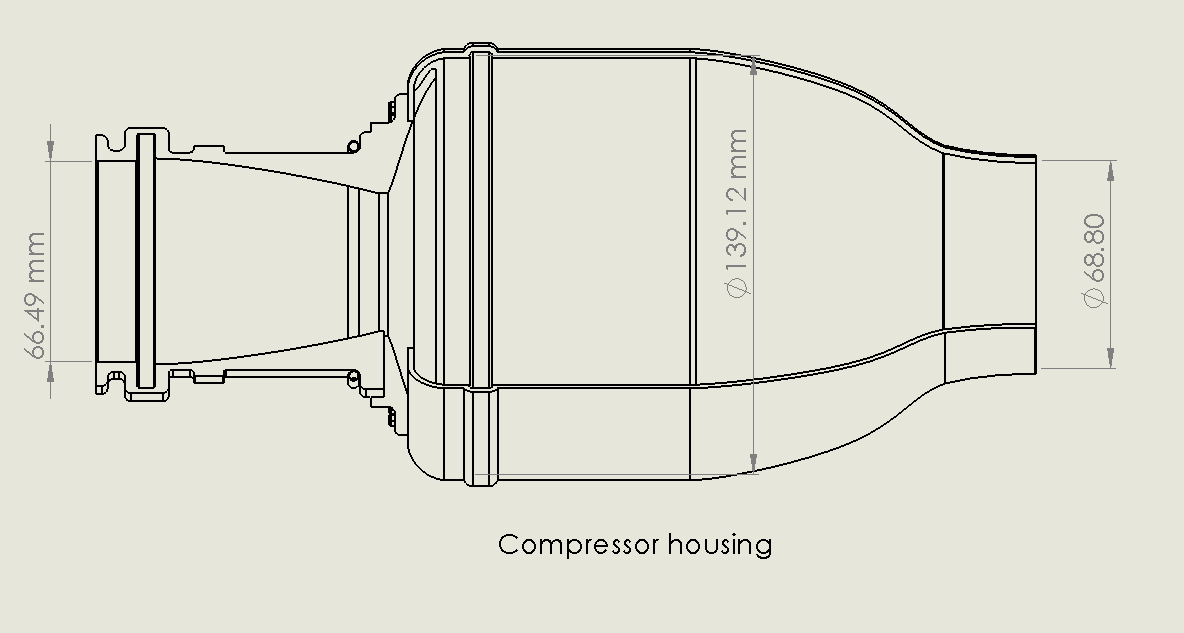

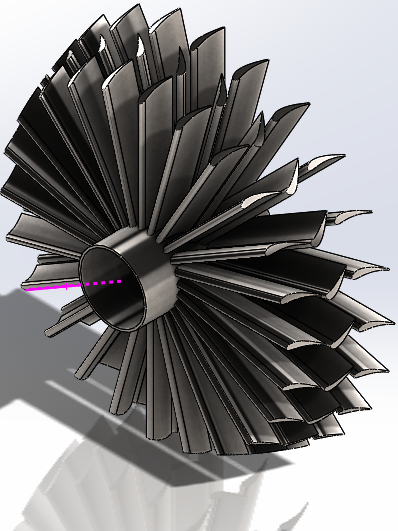

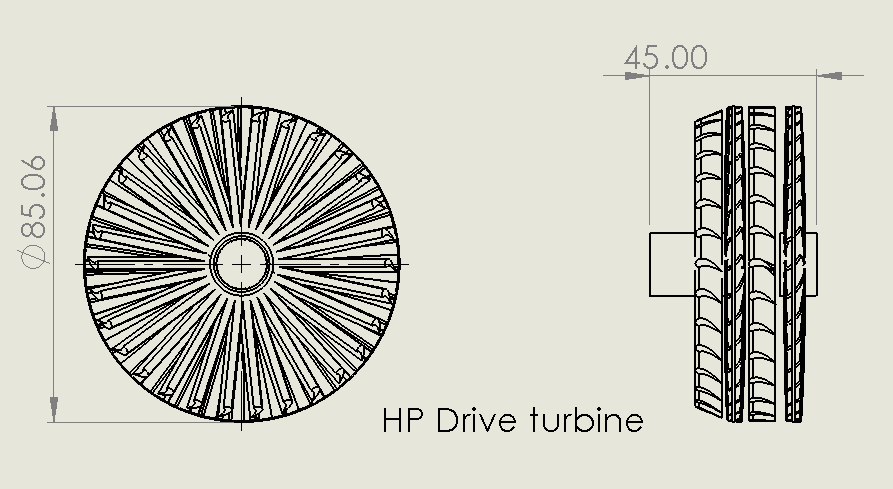

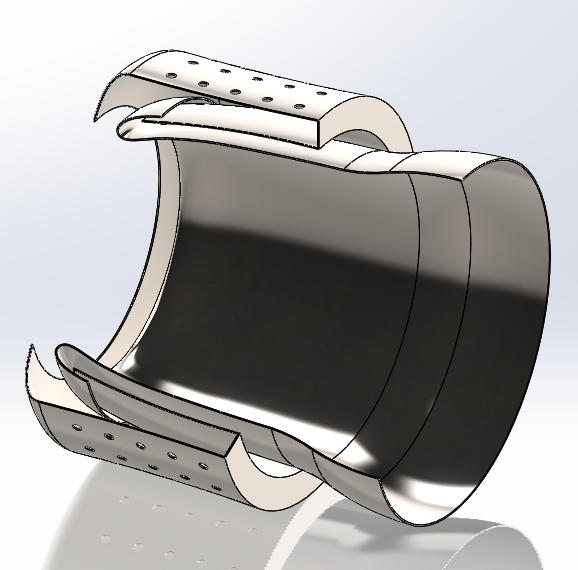

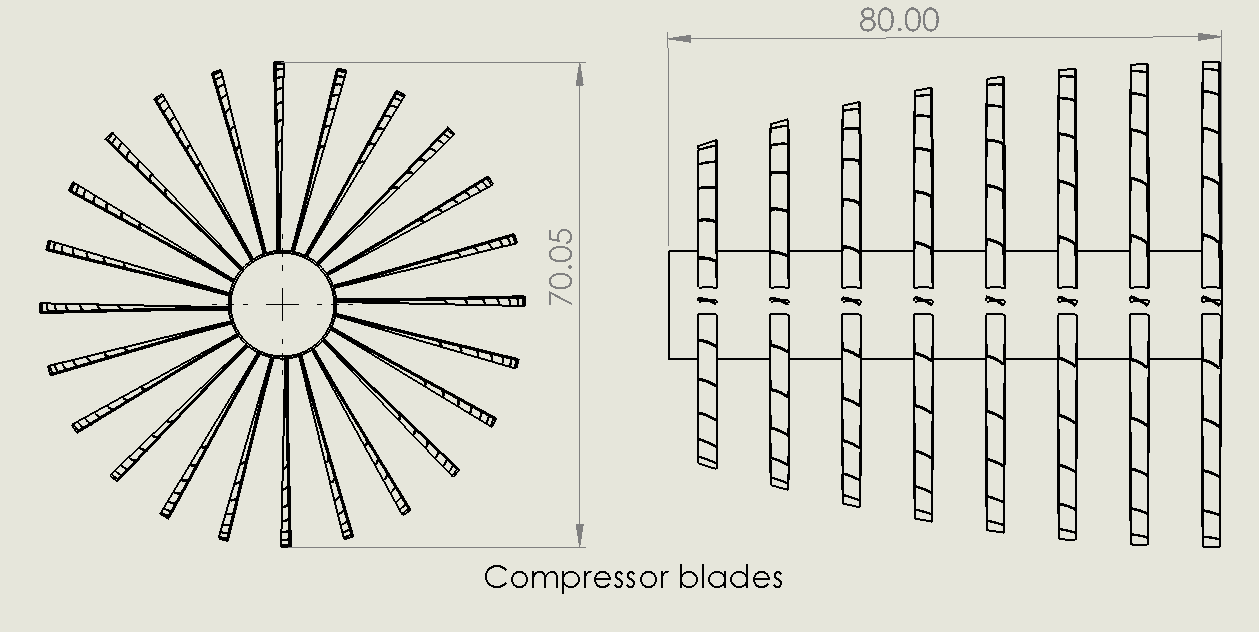

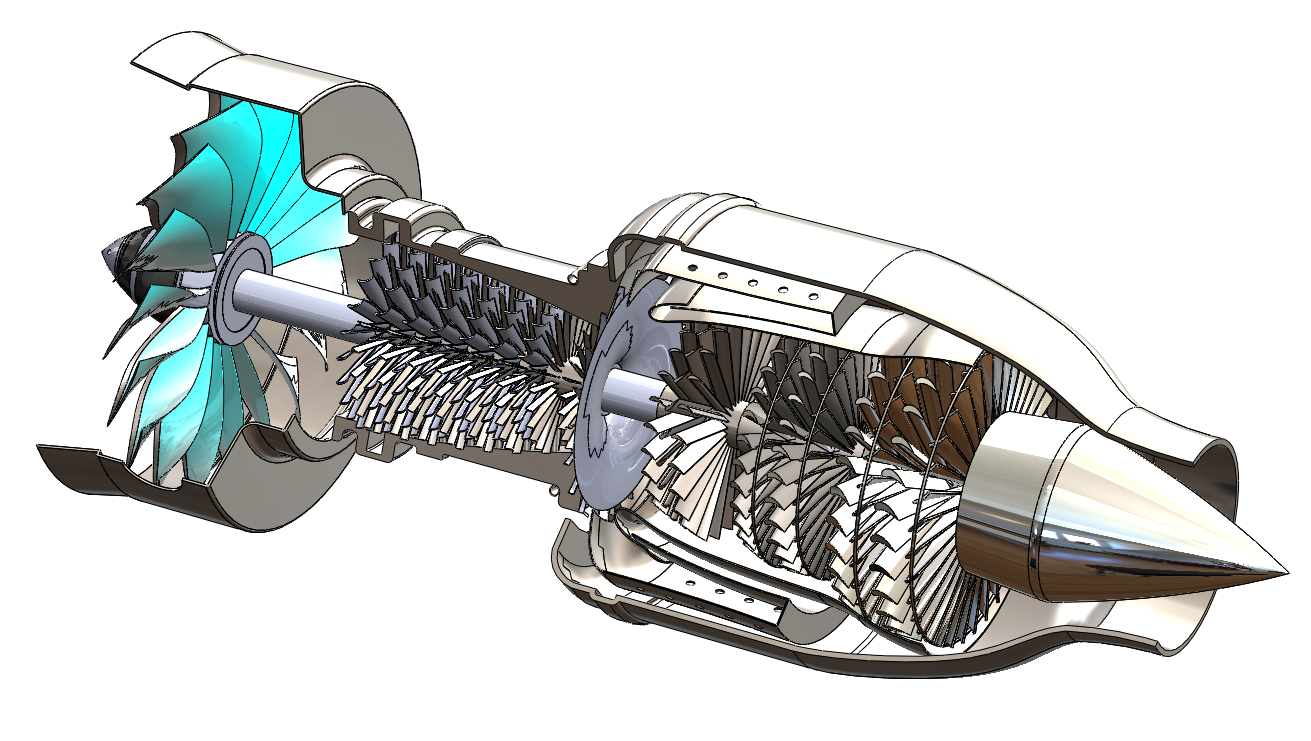

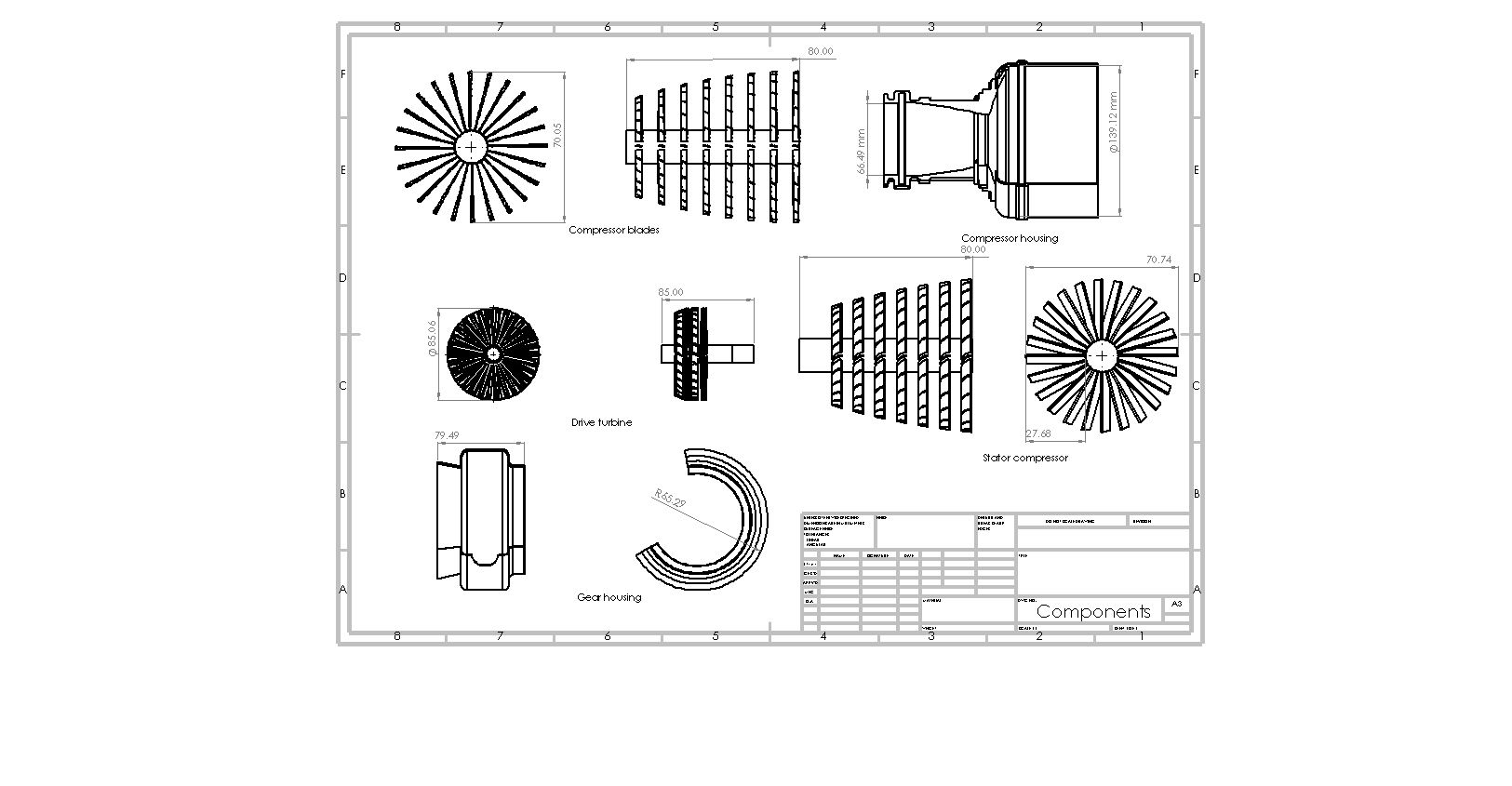

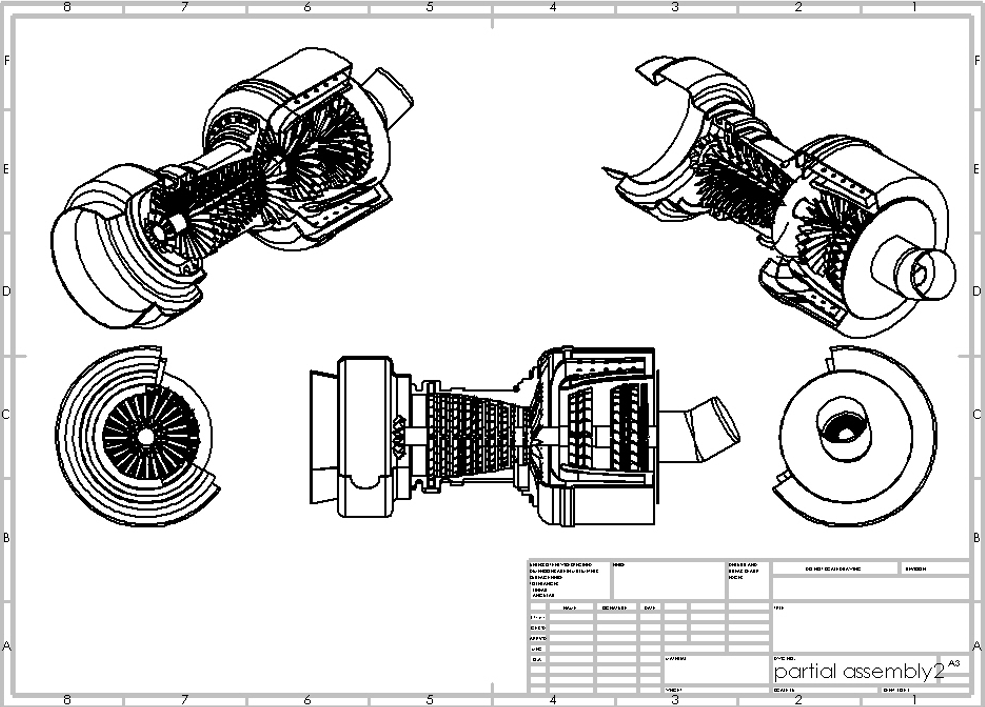

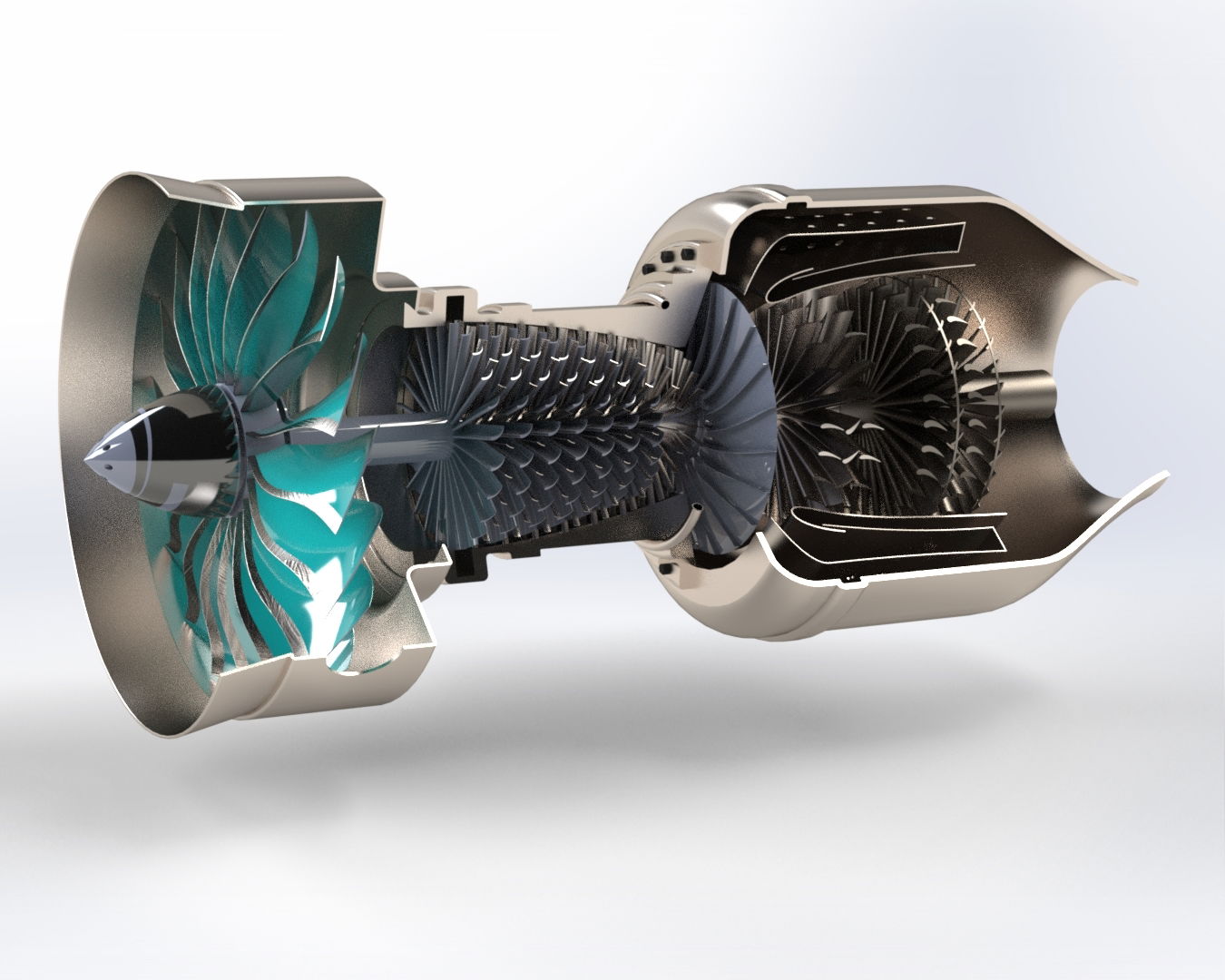

Jet Engine

Jet engine project modelled out of 9 complex parts as shown below

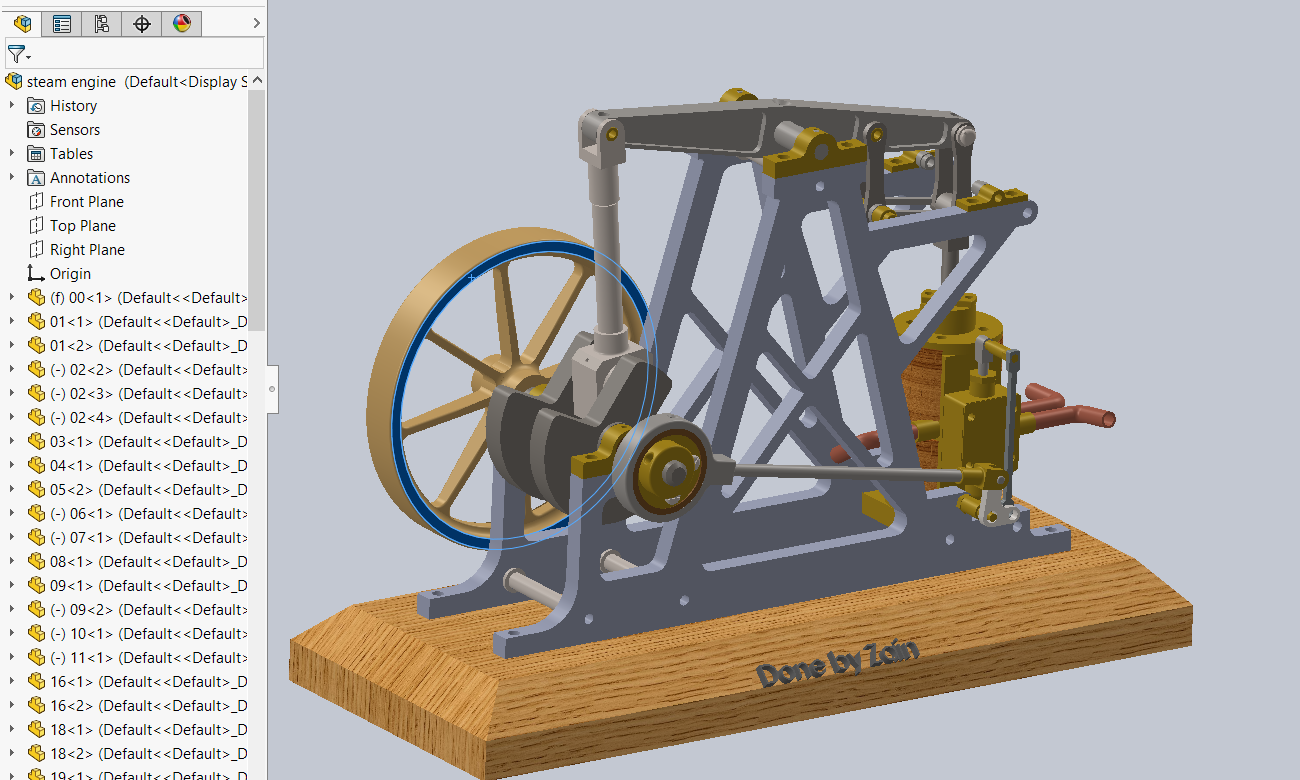

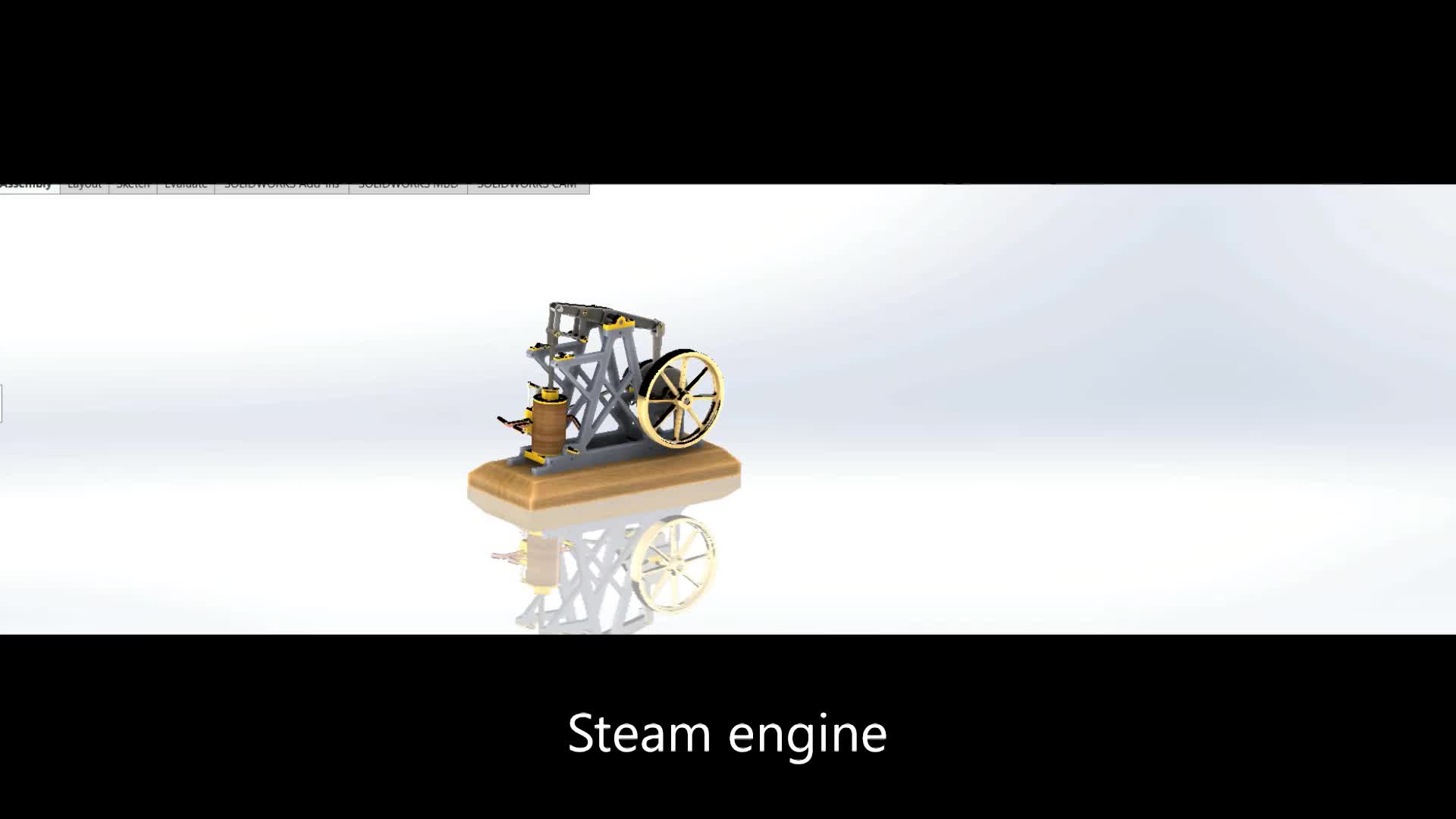

Steam Engine

Steam engien modelled and assembled from scratch. The engine required 37 differant parts to be completed.

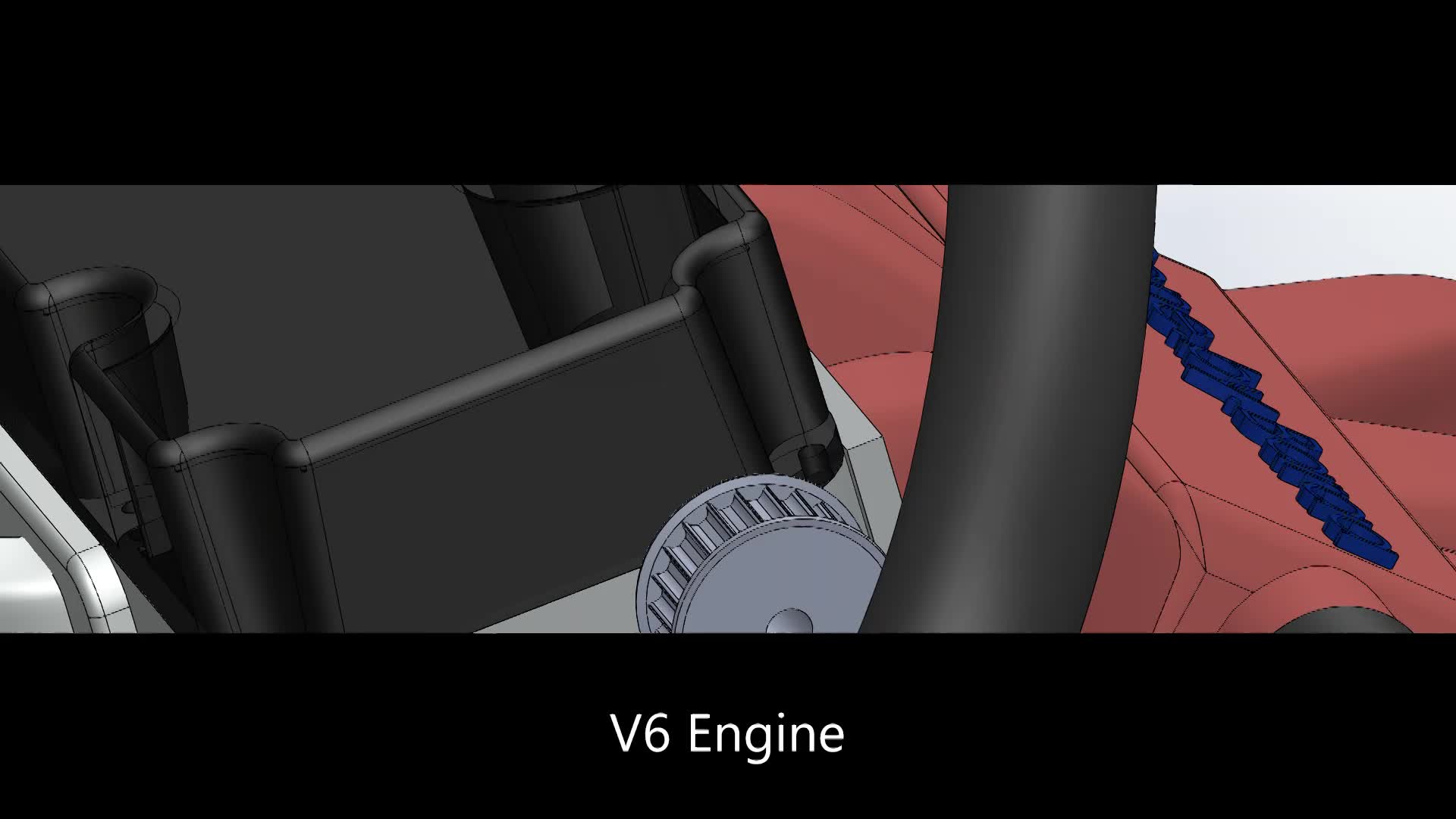

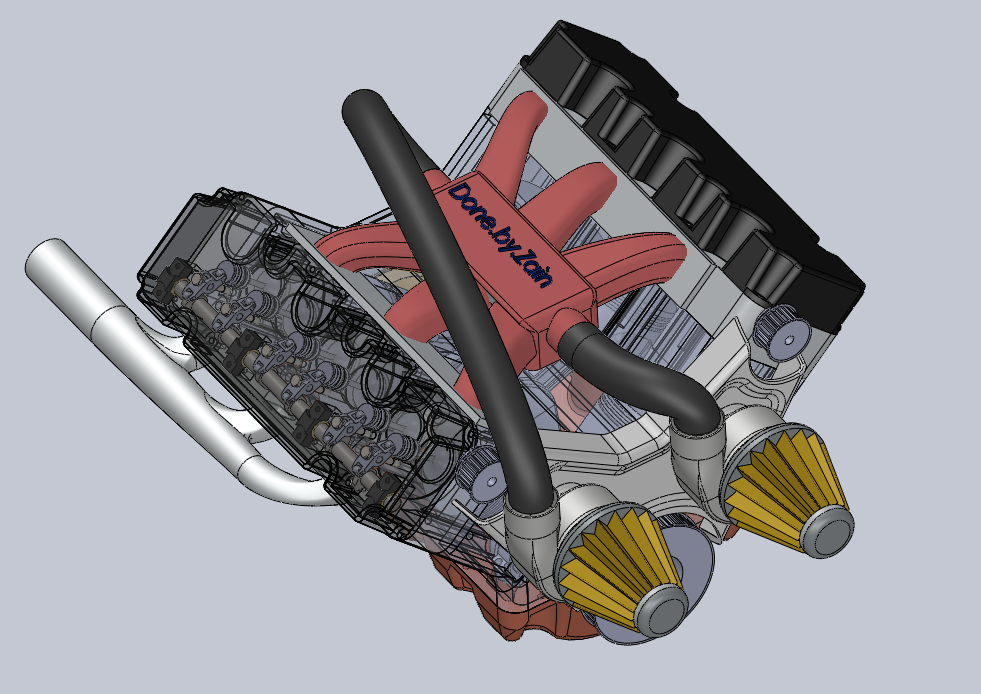

V6 Cylinders Internal Combustion Engine

Modelled out of 32 differant part and 216 have been assembeled to complete the Engine, as shown below.

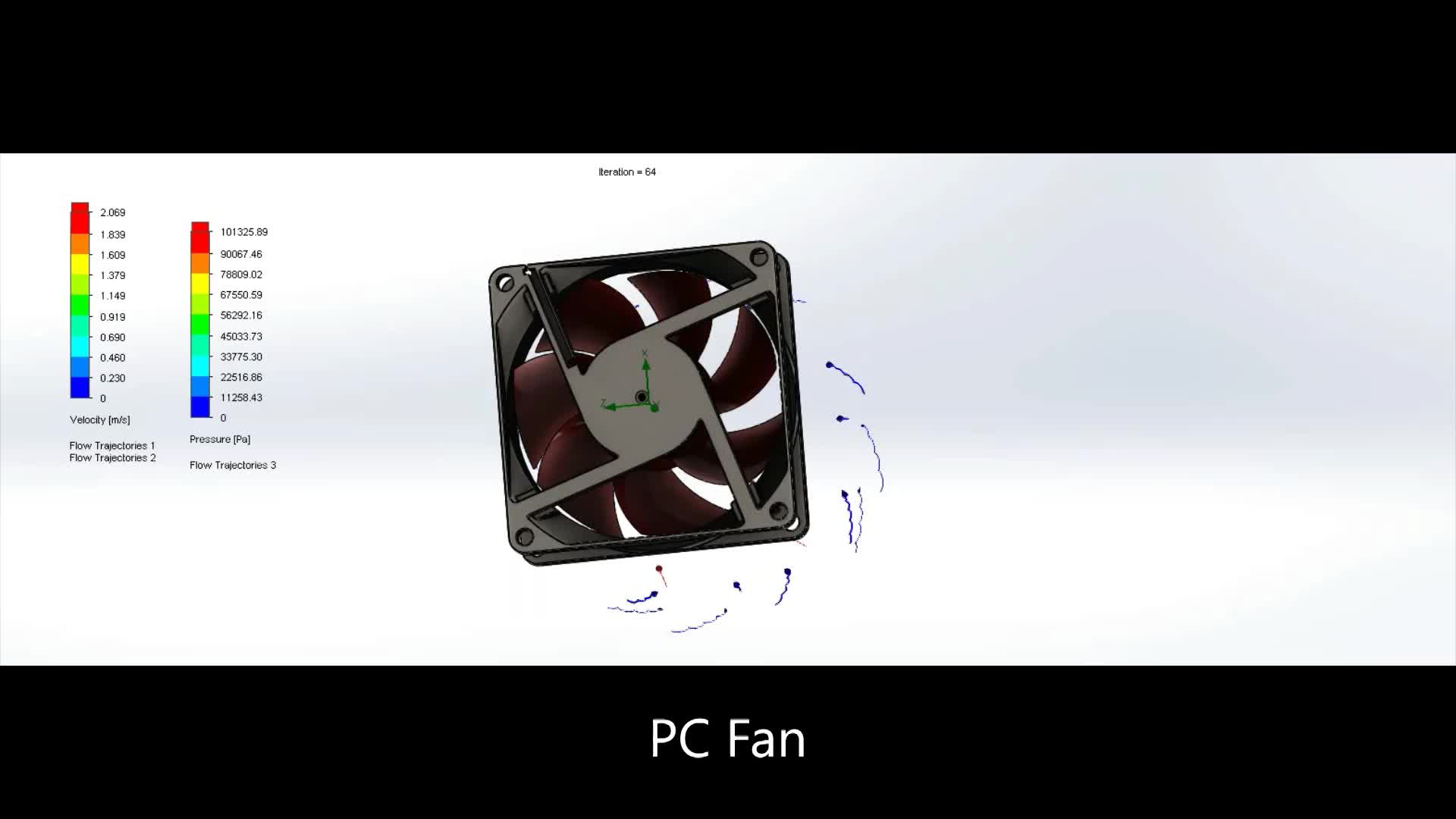

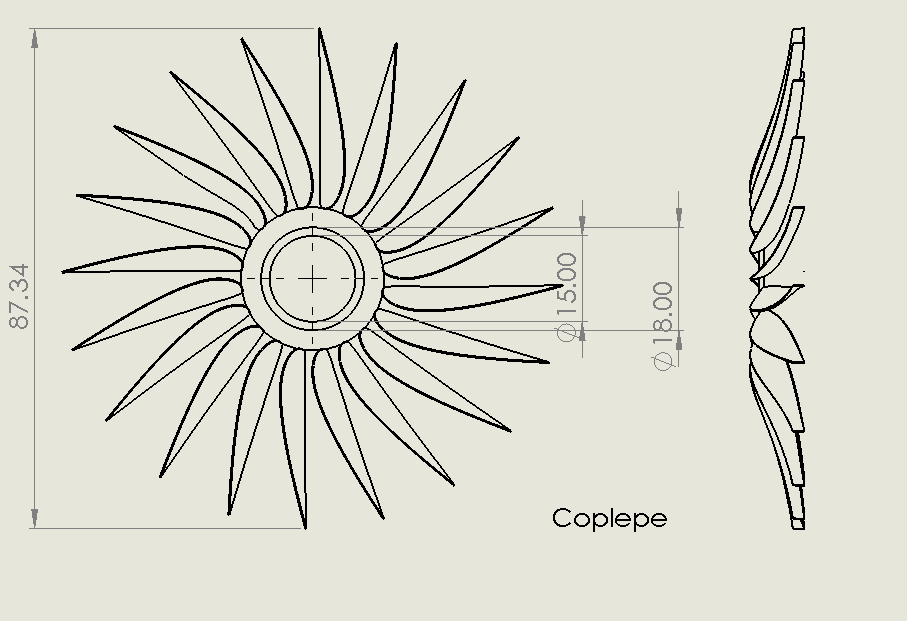

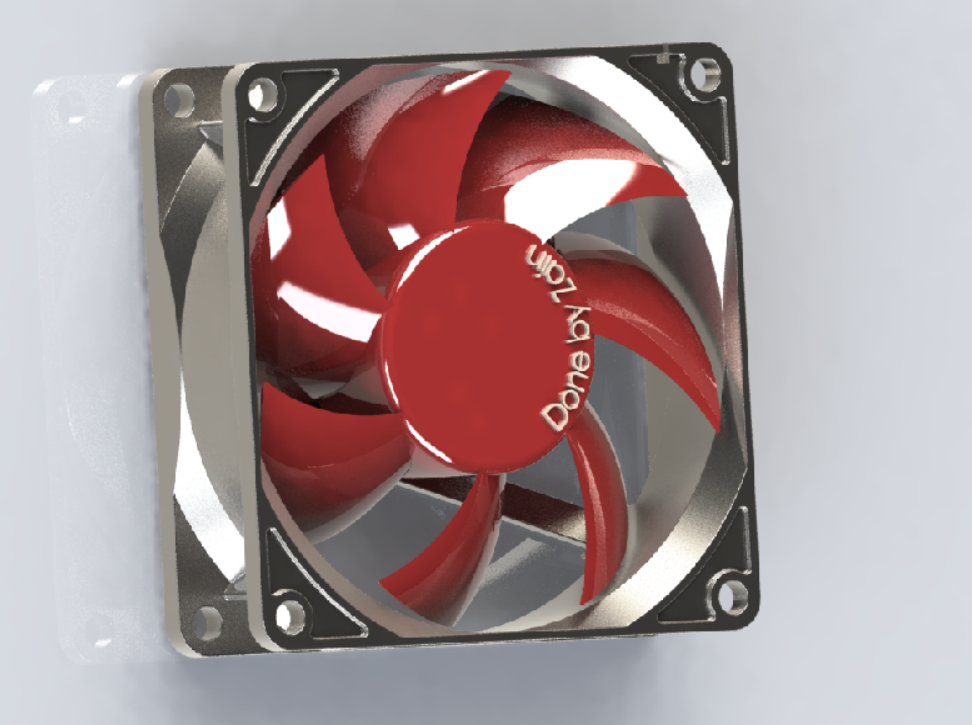

PC Fan

One of my first CFD model, have modelled the fan from scratch then applied an external flow simulation using SolidWorks solver.

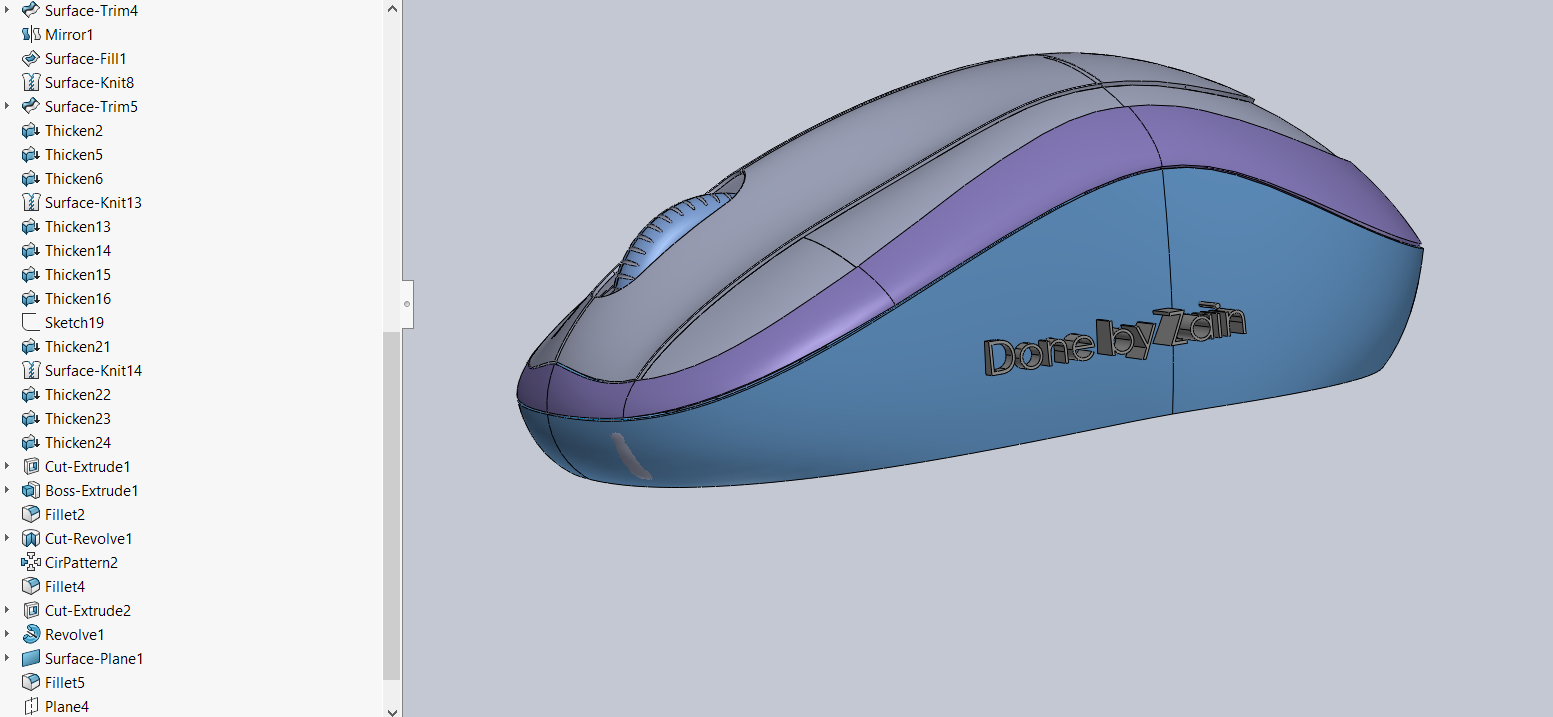

3D Surfacing (Mouse)

As a practice on Surfacing, modelling my mouse was very interesting.

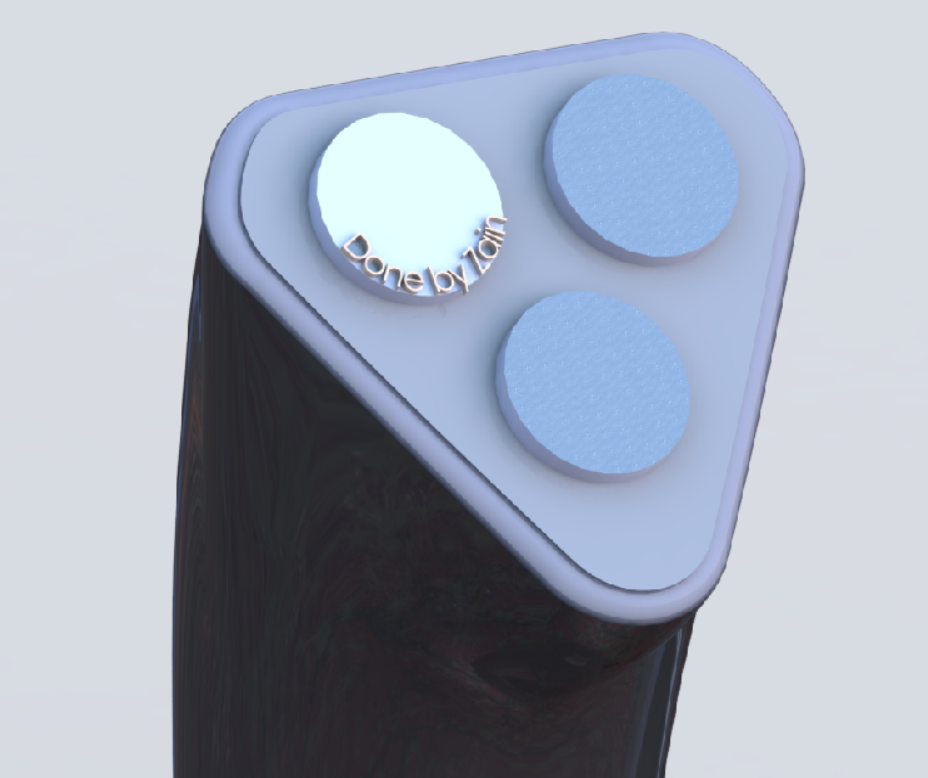

3D Surfacing (Shaving machine)

Simple shaving machine as practice on using surfacing features on SolidWorks.

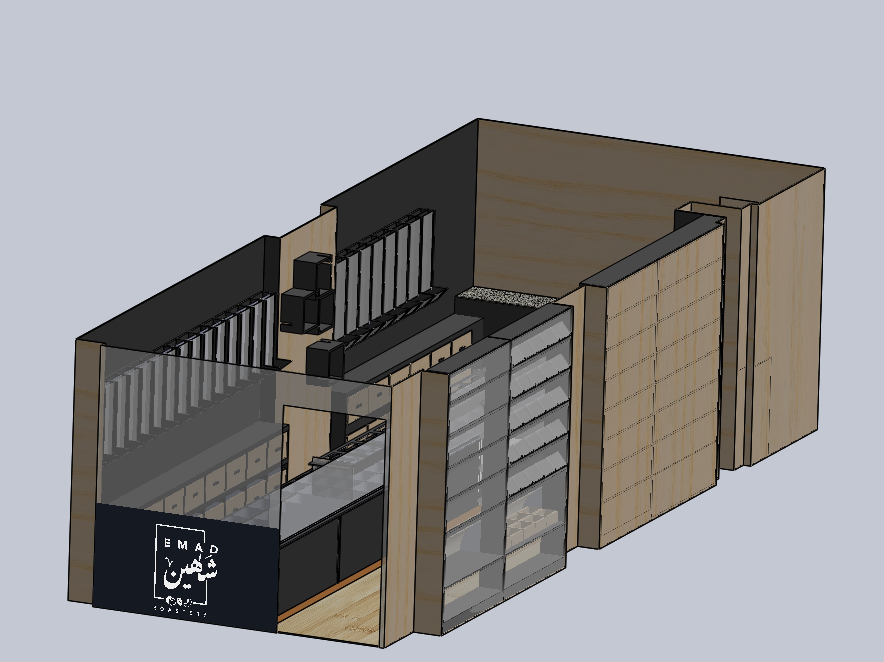

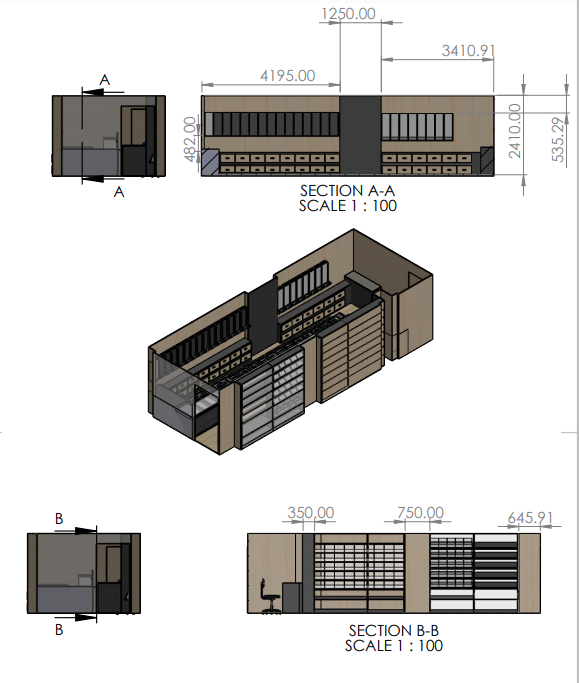

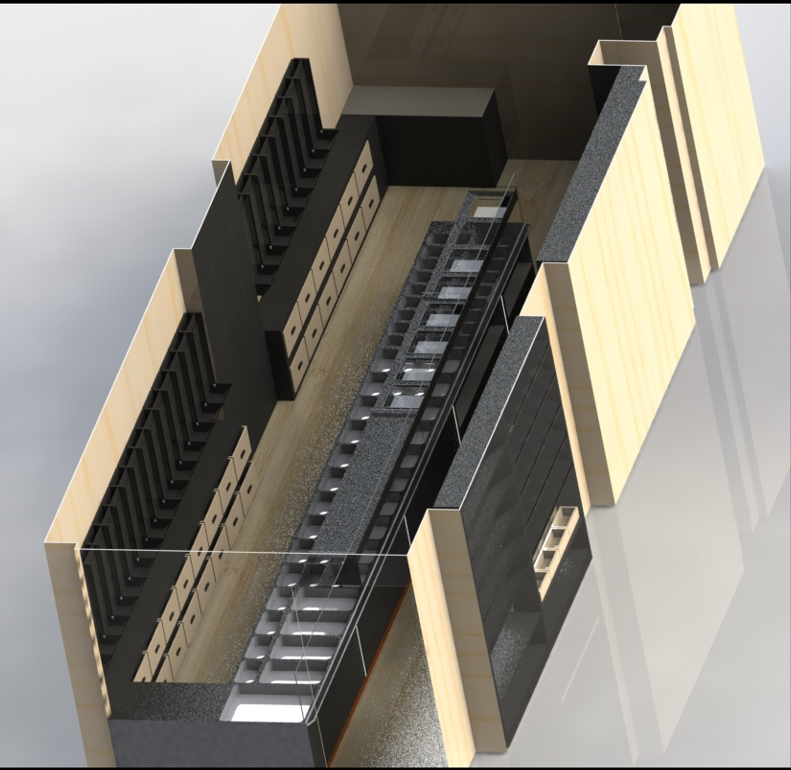

Nuts shop

With 15 differant parts and more than 120 parts after assembly a whole nuts shop has been designed and applied in real world (Shaheen nuts).

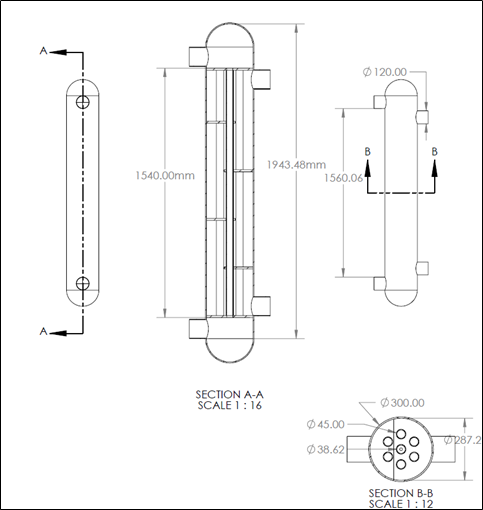

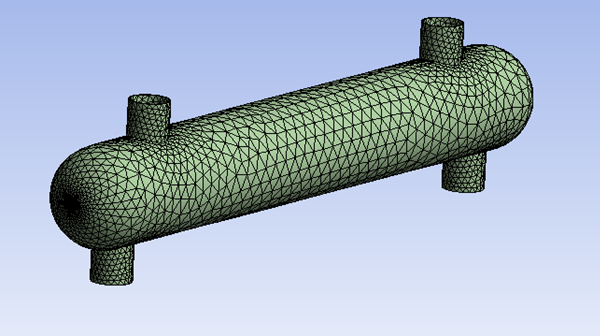

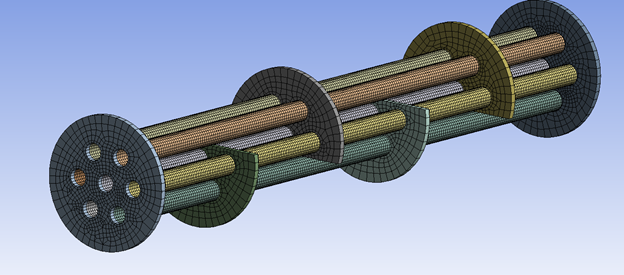

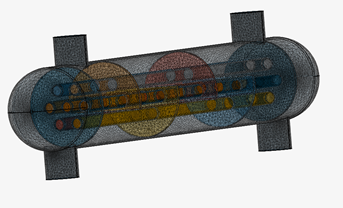

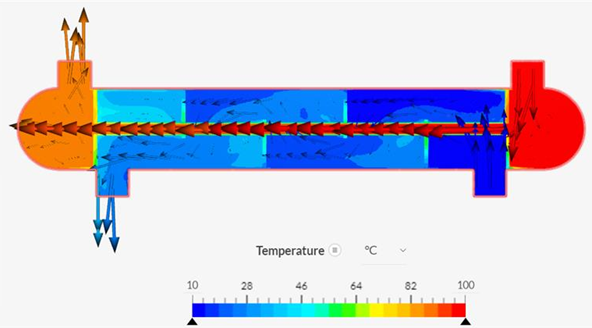

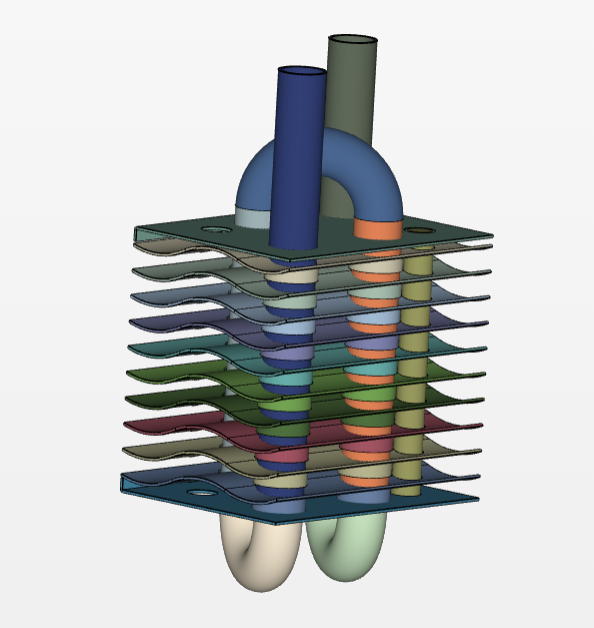

Shell and tube heat exchanger

Shell first mesh(Ansys)

Simscale Meshing cloud backage

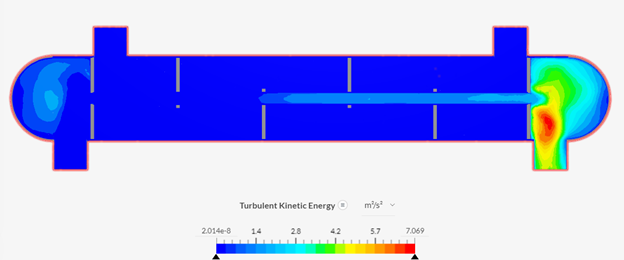

Simscale CFD results

Turbulance kinetic energy

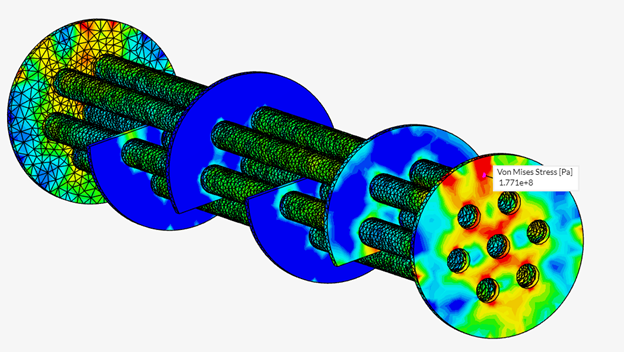

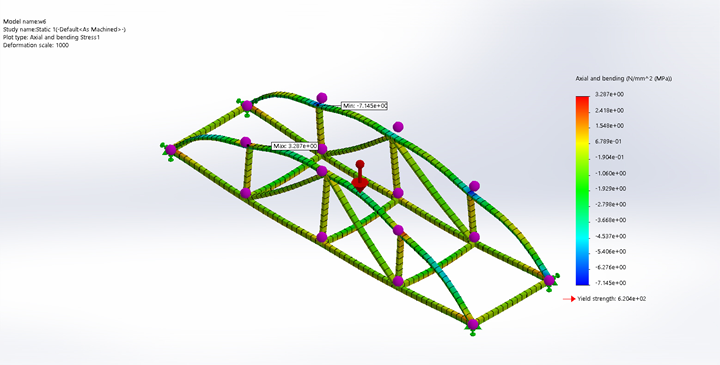

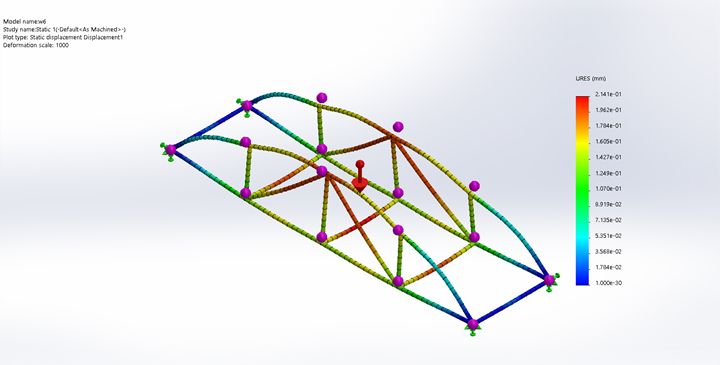

Thermomechanical loads

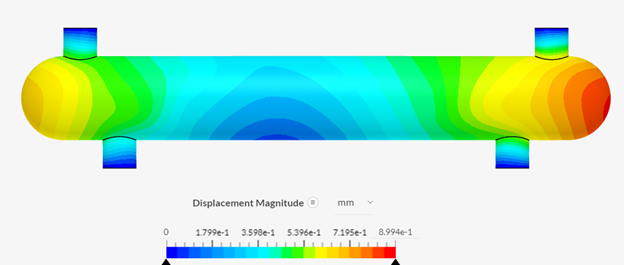

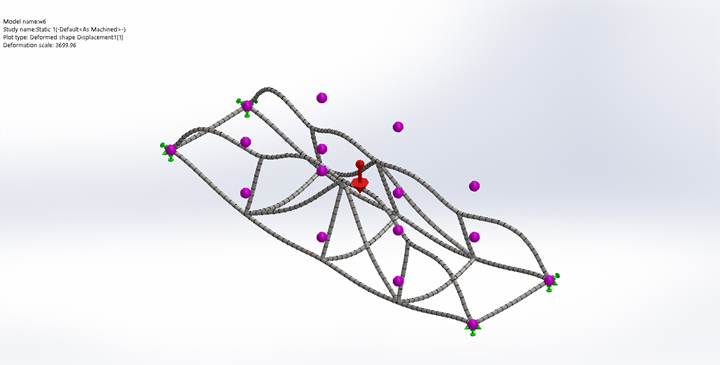

Resulted displacement on the shell body (factored by1)

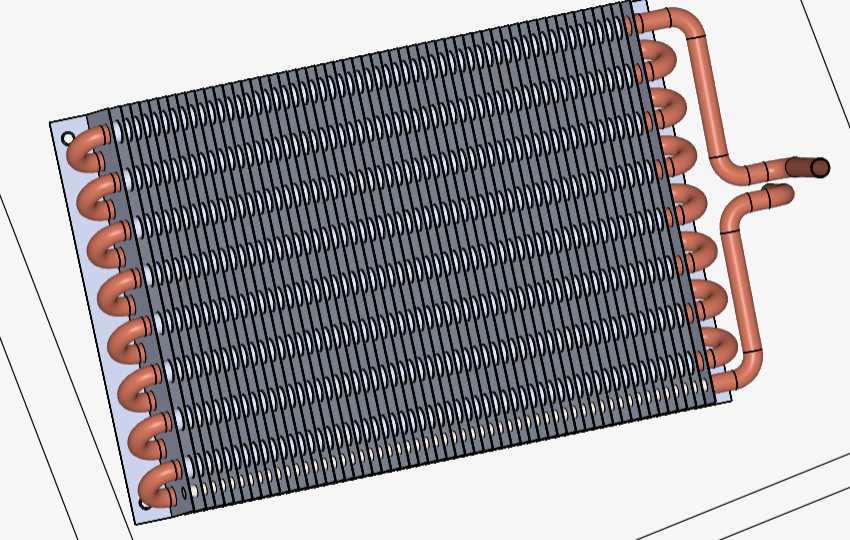

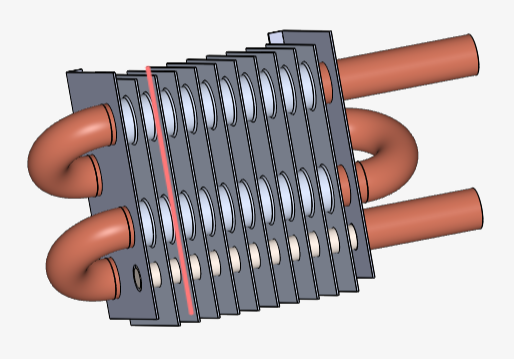

Finned heat exchanger

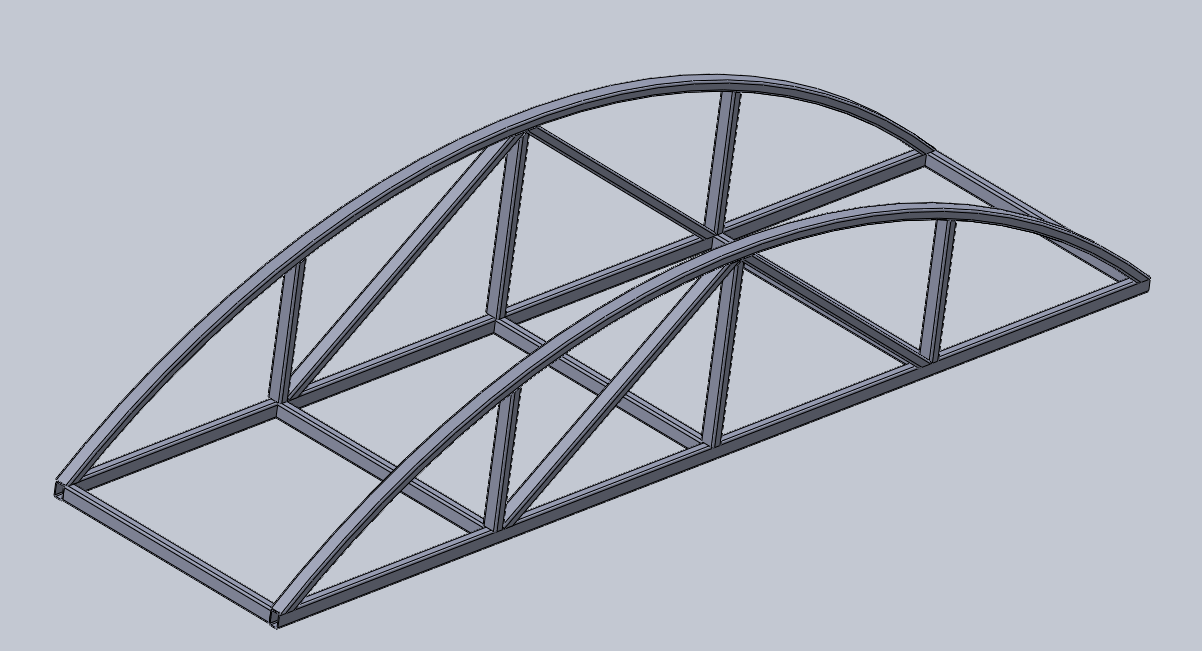

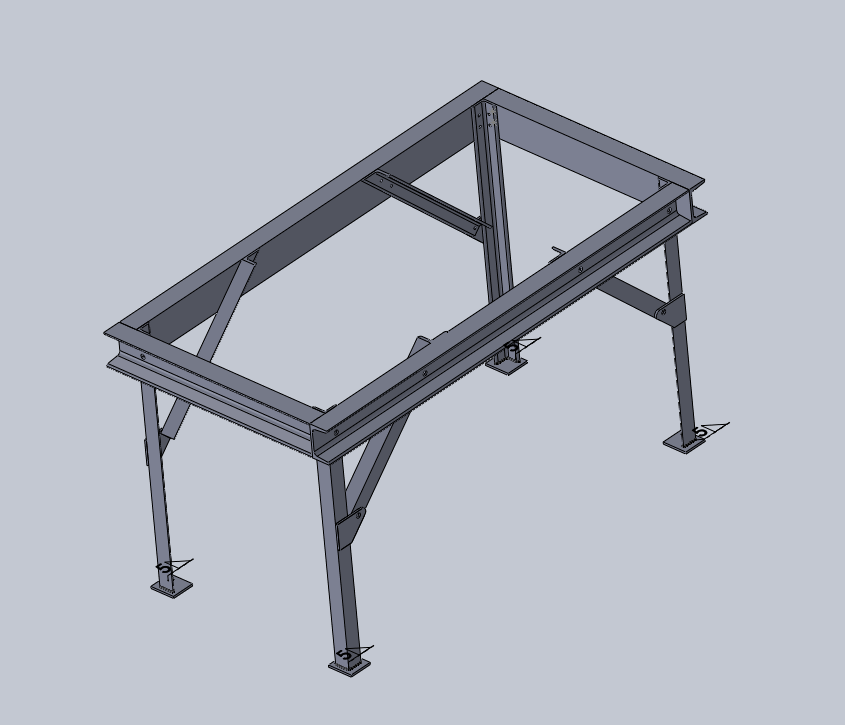

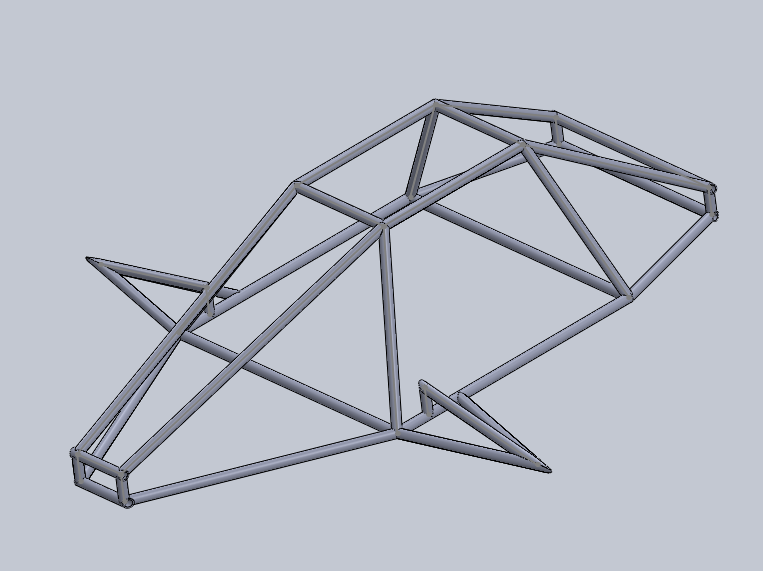

Weldment Projects

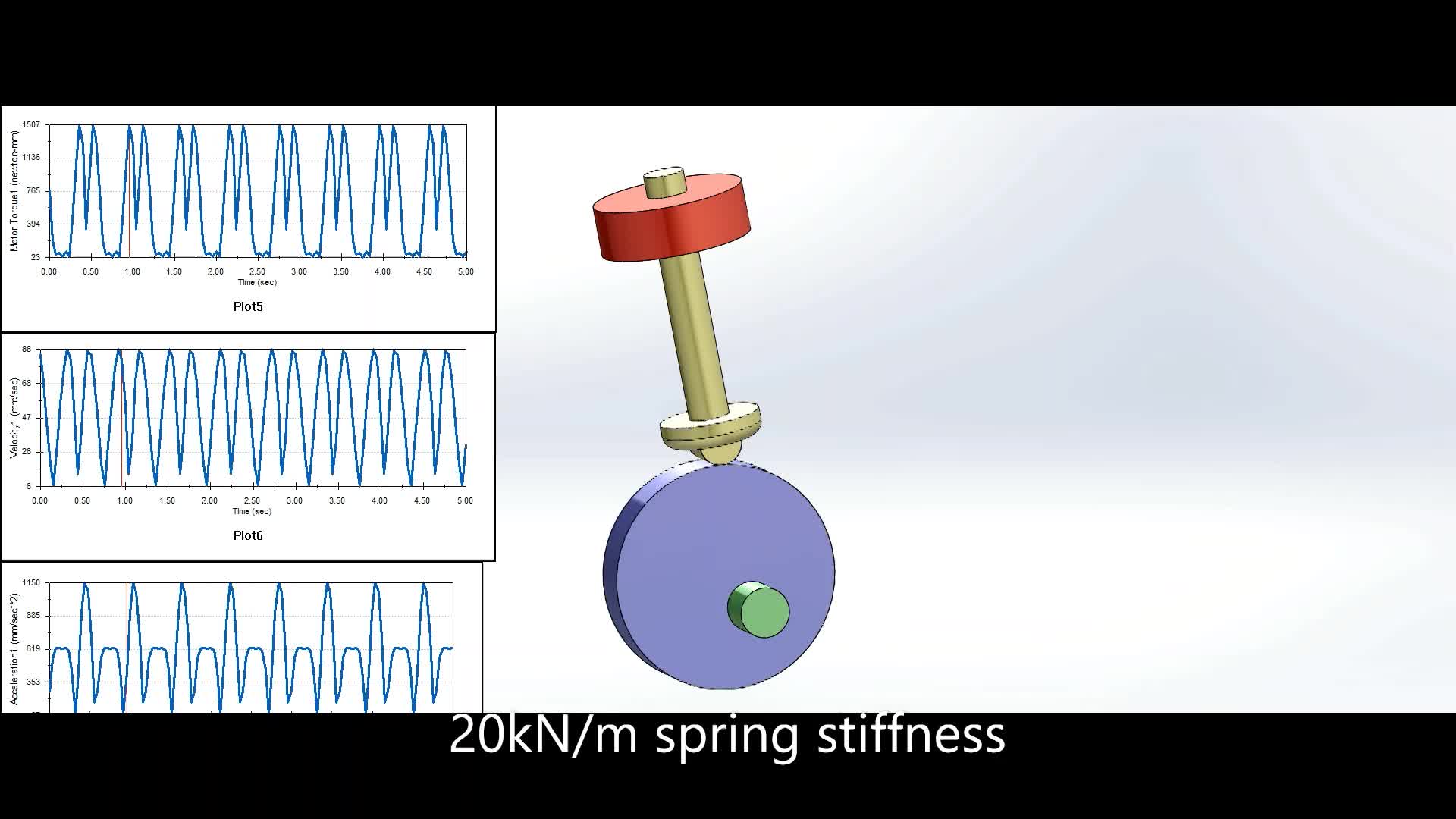

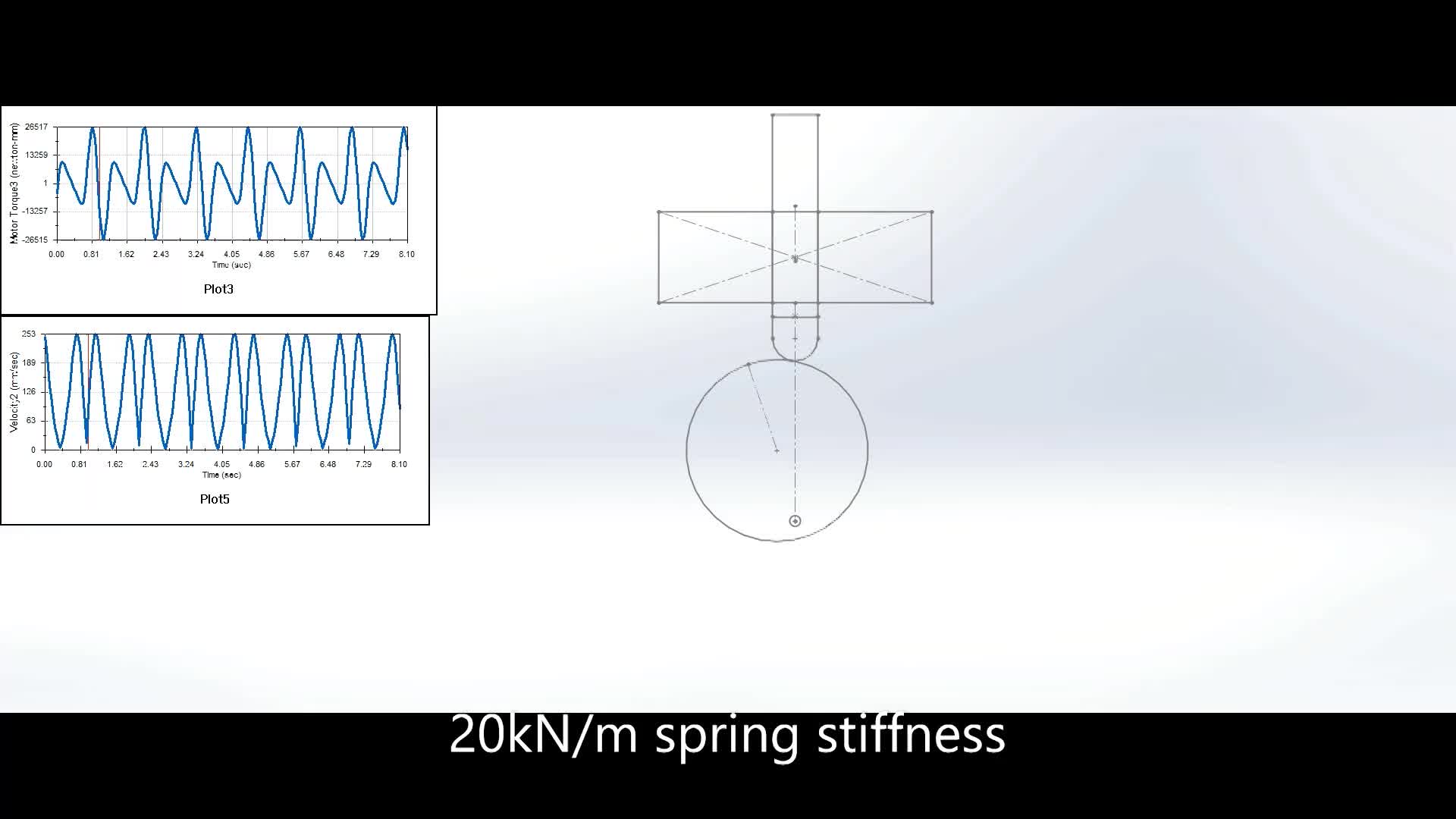

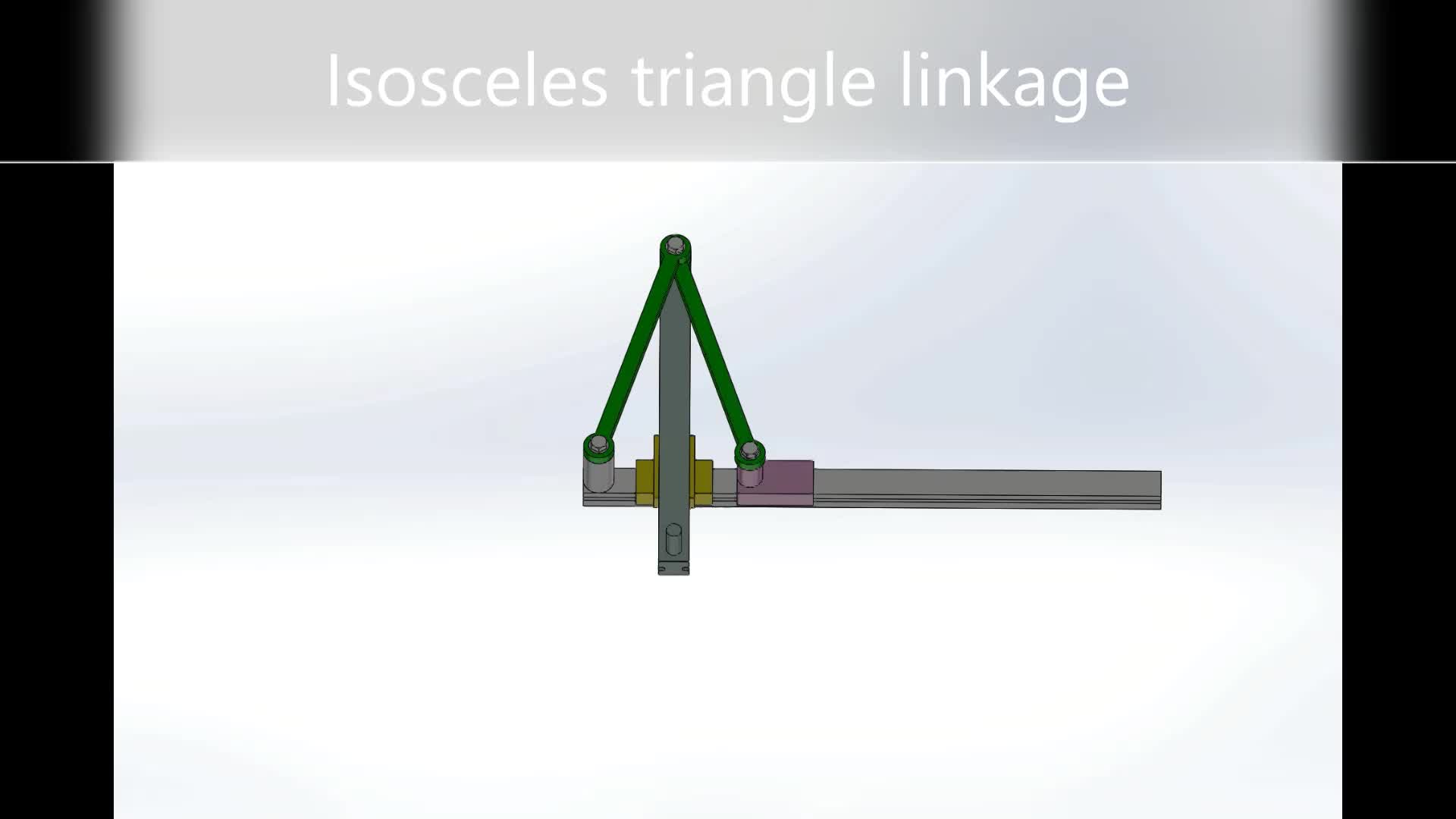

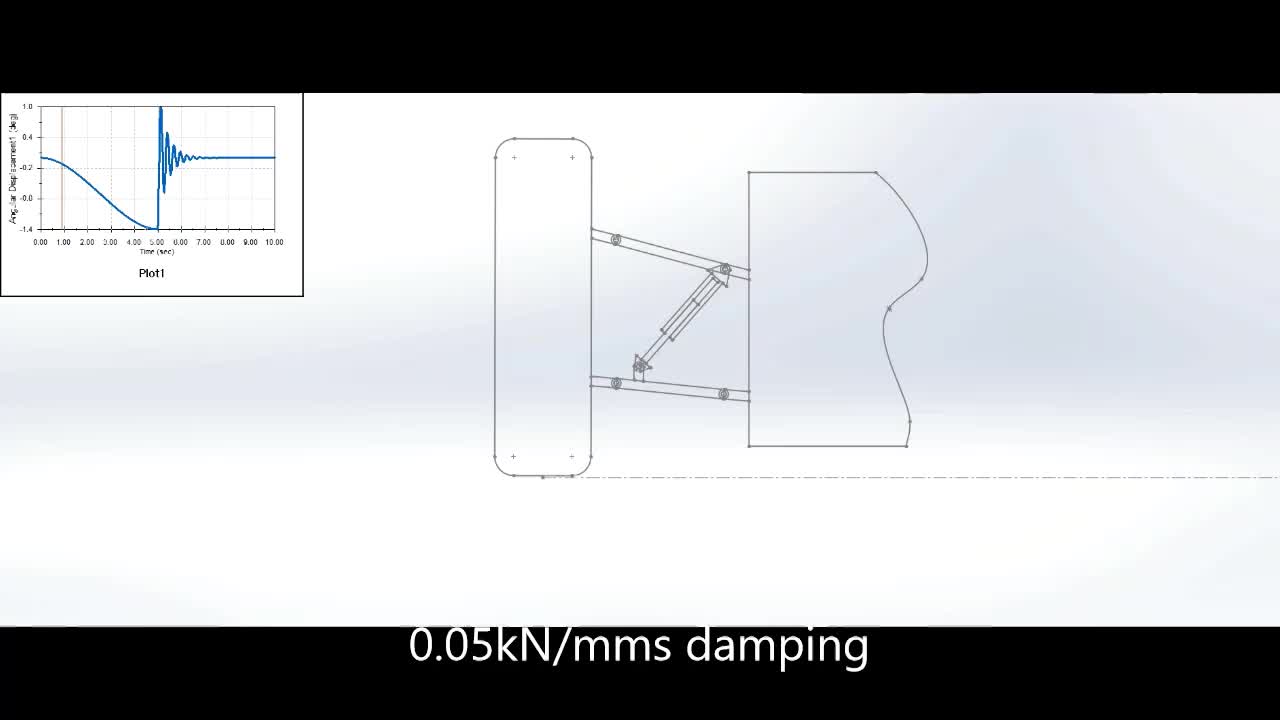

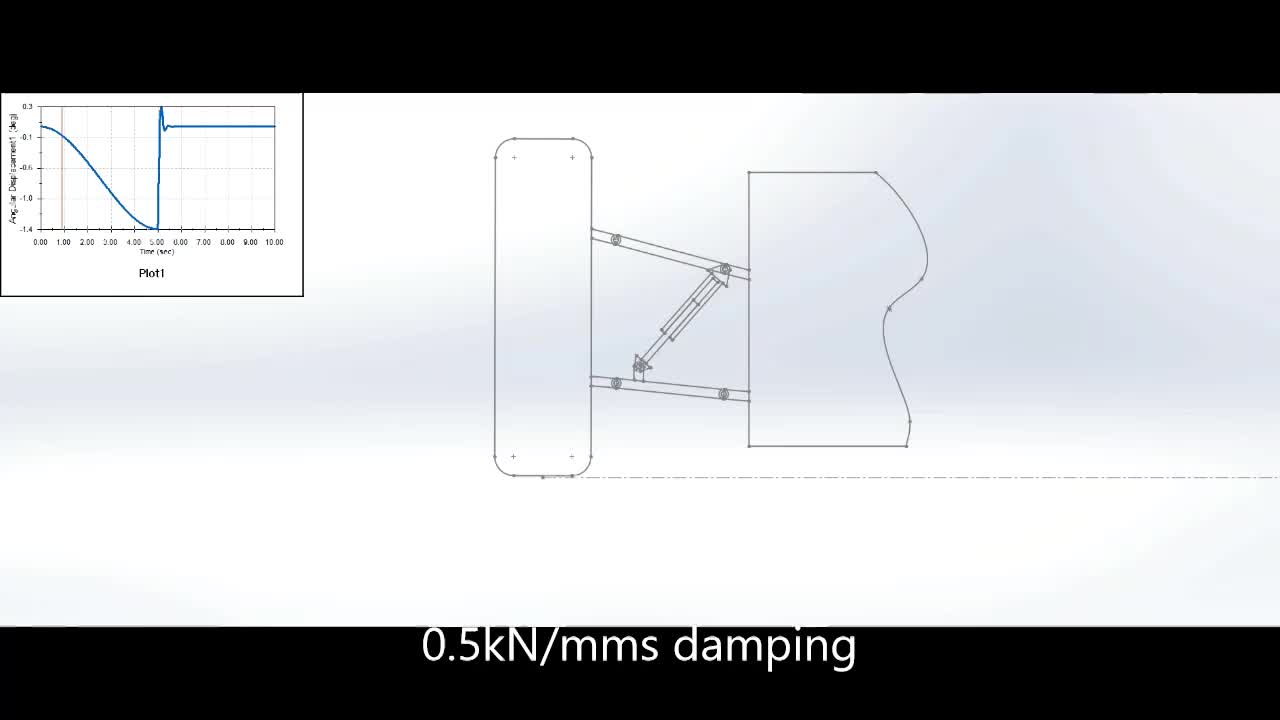

Motion analysis